An industrial engineer is a person who uses their knowledge to improve products, processes and engineering. Industrial engineers use shaker tables for product testing under various temperatures, humidity and vibrations. Failure data can then be used to improve manufacturing procedures and engineering. Simple changes such as mold-resistant coatings can make a big difference in the quality and durability of a product. Even the smallest changes such as locking up a place can greatly improve a product’s lifespan.

Job description

You should carefully write your job description if you're considering a career in industrial engineering. It is the people who are able to combine technical expertise and human intelligence that make industrial engineers the most successful. A well-written job description will help you attract top candidates. Monster's engineering job listings can give you some ideas on how to write a job description. Begin with a persuasive introduction that highlights the company's benefits. Your employer should be attractive to you, whether you are looking to join a well-respected brand, an innovative start up, or a young, dynamic company with a creative, open atmosphere.

Aside from excellent technical skills, industrial engineers must also have exceptional communication skills. An industrial engineer must be able communicate well with everyone involved in industrial processes. He or she must also know how to persuade employees and management that his or her proposed approaches will improve efficiency. A successful relationship management approach leads to greater productivity. It isn't just technical skills that are essential in the job of an industrial engineer.

Education requirements

An education in the field of industrial engineering is necessary for a position as this one involves a great deal of math and analytical skills. A strong communication skill is also essential for industrial engineers. They are expected to communicate the results to others. They must also be able design processes and designs that lower labor costs. You will be able to succeed in this area if you have a degree in the field. These are the most important educational requirements for this job.

In addition to a college degree, industrial engineers must also have excellent communication and interpersonal skills, since they work closely with other professionals and are the link between the business and technical sides of an organization. To communicate effectively with employees and business leaders, industrial engineers need to have strong communication and analytical skills. This profession requires excellent problem-solving and leadership skills. A high level of technical and mechanical competence is required for industrial engineers.

There are many career options

There are many career paths available for those who are interested in industrial design. Although most industrial engineers start in manufacturing, other options include hospitals or government agencies. Industrial engineers may also find work in the food industry, educational agencies, retail trade, professional trade associations, and computer service centers. There are many jobs available for industrial engineers. Here are some of the best. Read on to find out more about the various career opportunities available to you.

A industrial engineer is able to focus on getting the job done efficiently and effectively. Their job requires them to balance several factors such as time, number of workers needed, available technology, and actions workers must take. They must also be aware of safety and environment concerns. Many industrial engineers also participate in quality assurance and supply chain management. This field is particularly important because industries are constantly looking for ways to reduce costs while simultaneously increasing productivity. These experts can also assist in the development of new product applications or optimizing work flow within an organisation.

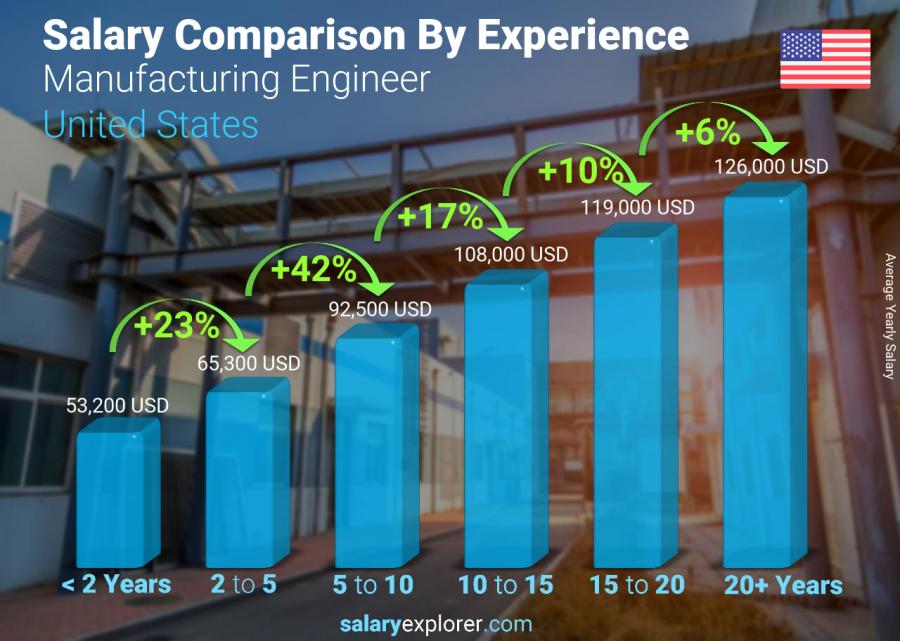

Salary

In 2004 the average Industrial Engineer salary was $87,513 USD, and that figure is expected to increase to $114,146 by 2020. However, the salary is highly dependent on the industry that one works in. The salaries of people who work in high-growth industries are more likely to be raised. Bonus figures for Industrial Engineers change frequently and are often moderate. The majority of bonus recipients are part of the revenue generation process. An industrial engineering degree is necessary to receive the best possible salary.

An industrial engineer must have a bachelor’s degree to be successful. Some employers, however, prefer PhDs. The average salary for an industrial engineer in the United States is $56,000 to $121,000. However, this number can fluctuate greatly. While an industrial engineer can work in an office setting, many jobs require overtime and protective attire. You need to have a lot of flexibility.

FAQ

What do we need to know about Manufacturing Processes in order to learn more about Logistics?

No. You don't have to know about manufacturing processes before learning about logistics. Understanding the manufacturing process will allow you to better understand logistics.

What skills does a production planner need?

A production planner must be organized, flexible, and able multitask to succeed. Effective communication with clients and colleagues is essential.

What types of jobs can you find in logistics

There are many kinds of jobs available within logistics. Here are some:

-

Warehouse workers – They load and unload pallets and trucks.

-

Transportation drivers: They drive trucks and trailers and deliver goods and make pick-ups.

-

Freight handlers: They sort and package freight in warehouses.

-

Inventory managers – These people oversee inventory at warehouses.

-

Sales reps are people who sell products to customers.

-

Logistics coordinators – They plan and coordinate logistics operations.

-

Purchasing agents – They buy goods or services necessary to run a company.

-

Customer service representatives are available to answer customer calls and emails.

-

Shipping clerks – They process shipping orders, and issue bills.

-

Order fillers - They fill orders based on what is ordered and shipped.

-

Quality control inspectors - They check incoming and outgoing products for defects.

-

Other - Logistics has many other job opportunities, including transportation supervisors, logistics specialists, and cargo specialists.

What is meant by manufacturing industries?

Manufacturing Industries is a group of businesses that produce goods for sale. Consumers are those who purchase these products. These companies use a variety processes such as distribution, retailing and management to accomplish their purpose. They produce goods from raw materials by using machines and other machinery. This includes all types manufactured goods such as clothing, building materials, furniture, electronics, tools and machinery.

What are the goods of logistics?

Logistics involves the transportation of goods from point A and point B.

They include all aspects associated with transport including packaging, loading transporting, unloading storage, warehousing inventory management customer service, distribution returns and recycling.

Logisticians ensure that products reach the right destination at the right moment and under safe conditions. They assist companies with their supply chain efficiency through information on demand forecasts. Stock levels, production times, and availability.

They also keep track of shipments in transit, monitor quality standards, perform inventories and order replenishment, coordinate with suppliers and vendors, and provide support services for sales and marketing.

How is a production manager different from a producer planner?

A production planner is more involved in the planning phase of the project than a project manger.

Statistics

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

External Links

How To

Six Sigma and Manufacturing

Six Sigma is defined by "the application SPC (statistical process control) techniques to achieve continuous improvements." Motorola's Quality Improvement Department developed it at their Tokyo plant in Japan in 1986. Six Sigma's main goal is to improve process quality by standardizing processes and eliminating defects. Many companies have adopted Six Sigma in recent years because they believe that there are no perfect products and services. Six Sigma's main objective is to reduce variations from the production average. If you take a sample and compare it with the average, you will be able to determine how much of the production process is different from the norm. If there is a significant deviation from the norm, you will know that something needs to change.

Understanding how your business' variability is a key step towards Six Sigma implementation is the first. Once you understand that, it is time to identify the sources of variation. It is important to identify whether the variations are random or systemic. Random variations occur when people make mistakes; systematic ones are caused by factors outside the process itself. For example, if you're making widgets, and some of them fall off the assembly line, those would be considered random variations. You might notice that your widgets always fall apart at the same place every time you put them together.

Once you identify the problem areas, it is time to create solutions. That solution might involve changing the way you do things or redesigning the process altogether. After implementing the new changes, you should test them again to see if they worked. If they fail, you can go back to the drawing board to come up with a different plan.