You can choose from many North Carolina logistics providers to help you get your products or warehouse. They can offer a range services such as warehouse distribution, trucking, and even brokering transportation.

The Charlotte region in North Carolina is the perfect place to find distribution services. It is conveniently located between two major interstate highways, and offers easy access to large parts of the U.S. population as well as ports. It is also the home of the sixth busiest international airport in the country.

Charlotte offers many benefits for companies who wish to have their distribution centers there. You will have easy access from major ports as well as a convenient location within the inland city. There is also plenty of industrial space available that's affordable. It is also home of the nation's premier high-tech research center.

North Carolina's railway infrastructure continues to improve. The state is home to the largest consolidated railroad system in the country. The rail system serves 22 states. This means your company can reach more than 70% of the U.S.A. in just one business day.

North Carolina also offers two major shipping ports. Port of Wilmington (morehead city) offers full-service transportation to both coast and inland areas. The Port of Virginia is also accessible at Norfolk/Hampton Roads.

The state is home to several major aerospace companies, as well as a large number of other manufacturers. North Carolina also has several Foreign Trade Zones that make it an ideal location for exporting or importing products. Strong product demand is a result of a robust economy. This will continue to impact the global supply chain.

ACI Transport is a company that focuses on adaptability and integrity. It is also built around communication and customer service. ACI offers many transportation services to the building, medical, and chemical industries.

C&O Warehousing & Logistics, Raleigh-Durham has a modern warehouse area of 400,000 feet. The company is a provider of complete distribution services, built around modern warehouses.

The company is expanding to better serve the East Coast life sciences industry. The company is also partnering with a leading Food & Beverage company. Over the next few year, 300 new employees will be added to the company.

CSX has opened the CSX Carolina Connector intermodal terminal in Rocky Mount (NC) recently. This project earned the company the Hay Award for Excellence. CSX has also opened direct rail service from the Port of Wilmington. This is a significant boon for Rocky Mount's manufacturers.

North Carolina also has two full-service shipping points. Port City Logistics offers a variety of transportation services, including drayage trucking and warehouse distribution. Port City's warehouse area covers 3.5million square feet. Port City also offers brokered transportation solutions. Port City will invest $16 million to build a 150,000-square foot building in New Hanover County. New Hanover County will be able to create 75 jobs with this new building.

FAQ

What is the difference in Production Planning and Scheduling, you ask?

Production Planning (PP), is the process of deciding what production needs to take place at any given time. Forecasting and identifying production capacity are two key elements to this process.

Scheduling is the process of assigning specific dates to tasks so they can be completed within the specified timeframe.

How can manufacturing avoid production bottlenecks

Avoiding production bottlenecks is as simple as keeping all processes running smoothly, from the time an order is received until the product ships.

This includes both planning for capacity and quality control.

Continuous improvement techniques like Six Sigma are the best way to achieve this.

Six Sigma Management System is a method to increase quality and reduce waste throughout your organization.

It seeks to eliminate variation and create consistency in your work.

What is the responsibility of a logistics manager?

Logistics managers ensure that goods arrive on time and are unharmed. This is done by using his/her experience and knowledge of the company's products. He/she also needs to ensure adequate stock to meet demand.

What is production plan?

Production Planning includes planning for all aspects related to production. It is important to have everything ready and planned before you start shooting. It should also provide information about how best to produce the best results while on set. This information includes locations, crew details and equipment requirements.

It is important to first outline the type of film you would like to make. You may already know where you want the film to be shot, or perhaps you have specific locations and sets you wish to use. Once you have identified your locations and scenes, you can start working out which elements you require for each scene. You might decide you need a car, but not sure what make or model. In this case, you could start looking up cars online to find out what models are available and then narrow your choices by choosing between different makes and models.

After you have chosen the right car, you will be able to begin thinking about accessories. You might need to have people in the front seats. Or maybe you just need someone to push the car around. Maybe you want to change the interior color from black to white? These questions will help guide you in determining the ideal look and feel for your car. Another thing you can do is think about what type of shots are desired. What type of shots will you choose? Perhaps you want to show the engine or the steering wheel? These things will help you to identify the car that you are looking for.

Once you've determined the above, it is time to start creating a calendar. You can create a schedule that will outline when you must start and finish your shoots. Each day will include the time when you need to arrive at the location, when you need to leave and when you need to return home. It will help everyone know exactly what they have to do and when. Hire extra staff by booking them ahead of time. You should not hire anyone who doesn't show up because of your inaction.

When creating your schedule, you will also need to consider the number of days you need to film. Some projects take only a few days while others can last several weeks. You should consider whether you will need more than one shot per week when creating your schedule. Multiple takes at the same place will result in higher costs and longer completion times. You can't be certain if you will need multiple takes so it is better not to shoot too many.

Budget setting is another important aspect in production planning. As it will allow you and your team to work within your financial means, setting a realistic budget is crucial. You can always lower the budget if you encounter unexpected problems. However, you shouldn't overestimate the amount of money you will spend. If you underestimate the cost of something, you will have less money left after paying for other items.

Planning production is a tedious process. Once you have a good understanding of how everything works together, planning future projects becomes easy.

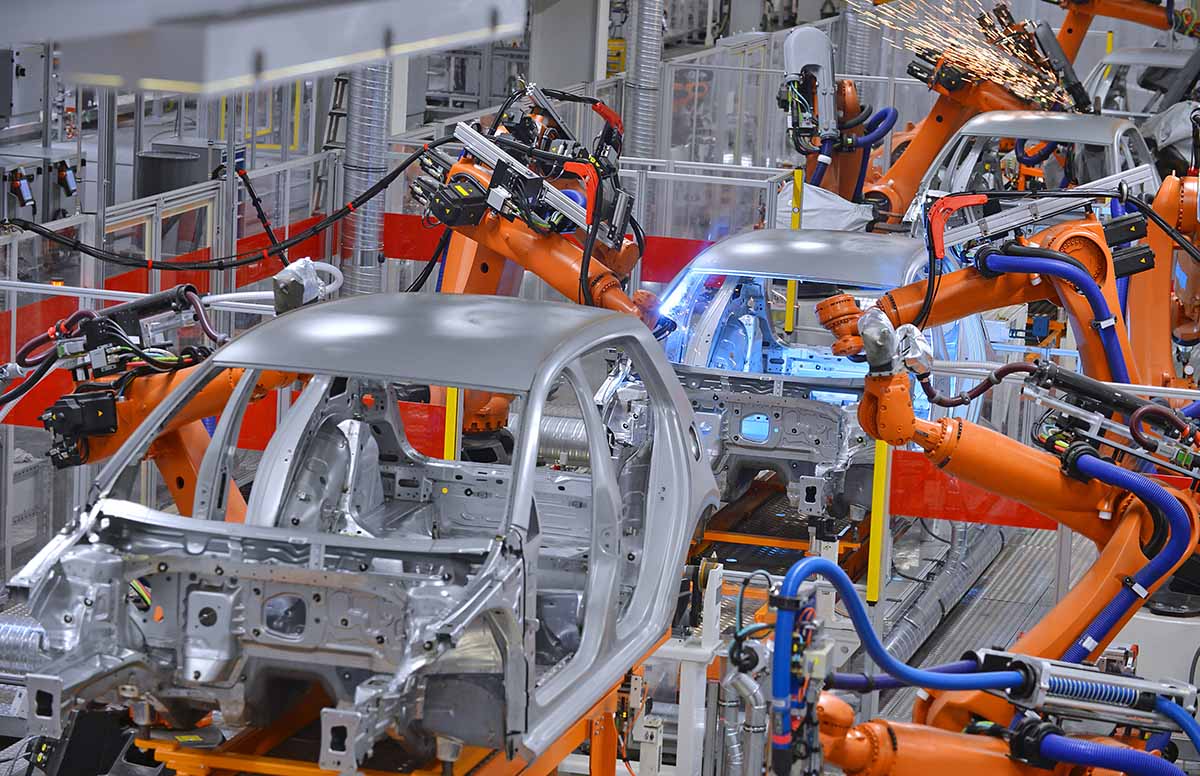

What are manufacturing and logistic?

Manufacturing is the act of producing goods from raw materials using machines and processes. Logistics covers all aspects involved in managing supply chains, including procurement and production planning. Logistics and manufacturing are often referred to as one thing. It encompasses both the creation of products and their delivery to customers.

Why is logistics important in manufacturing?

Logistics are essential to any business. They are essential to any business's success.

Logistics play an important role in reducing costs as well as increasing efficiency.

Statistics

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

External Links

How To

How to Use Six Sigma in Manufacturing

Six Sigma is "the application statistical process control (SPC), techniques for continuous improvement." It was developed by Motorola's Quality Improvement Department at their plant in Tokyo, Japan, in 1986. Six Sigma's core idea is to improve the quality of processes by standardizing and eliminating defects. Many companies have adopted this method in recent years. They believe there is no such thing a perfect product or service. The main goal of Six Sigma is to reduce variation from the mean value of production. If you take a sample and compare it with the average, you will be able to determine how much of the production process is different from the norm. If there is a significant deviation from the norm, you will know that something needs to change.

Understanding the nature of variability in your business is the first step to Six Sigma. Once you have a good understanding of the basics, you can identify potential sources of variation. It is important to identify whether the variations are random or systemic. Random variations are caused by human errors. Systematic variations can be caused by outside factors. If you make widgets and some of them end up on the assembly line, then those are considered random variations. If however, you notice that each time you assemble a widget it falls apart in exactly the same spot, that is a problem.

After identifying the problem areas, you will need to devise solutions. You might need to change the way you work or completely redesign the process. To verify that the changes have worked, you need to test them again. If they didn't work, then you'll need to go back to the drawing board and come up with another plan.