Materials engineers design and develop new materials to enable the technology of tomorrow. They work with metals, ceramics, plastics, and composites to create materials that meet certain chemical, electrical, and mechanical requirements.

What do materials engineers do?

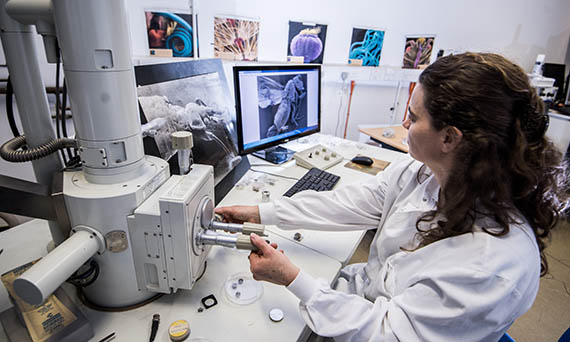

Material engineers process, test and develop raw materials to be used for a variety products like aircraft wings, computer chip, biomedical device, or golf clubs. These engineers evaluate and study the properties and structures of metals such as ceramics or plastics. They also examine nanomaterials which are extremely small substances.

The responsibilities of a materials engineer vary according to the specific type of materials that they are working with and the industry in which they are employed. However, they are often responsible for assessing production costs, quality control, creating budgets, and supervising technicians.

What is an materials science engineer (MSI)?

A materials scientist engineer is a person who works with various materials such as ceramics, metals and composites in order to make these materials stronger, lighter and more durable. They can develop new materials and improve existing ones.

What does a materials engineer need?

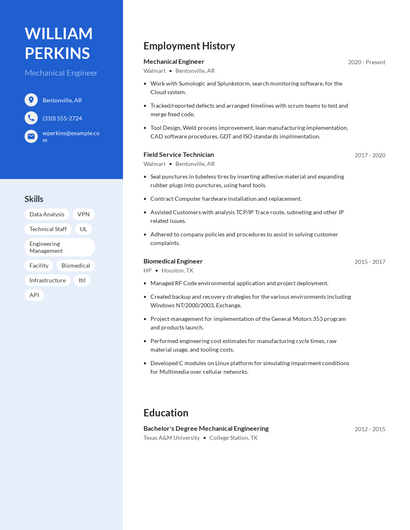

You will need a degree in engineering, materials science or a related field to become a Materials Engineer. This degree should include classroom and laboratory work with an emphasis on engineering principles. This program may take a couple of years to complete.

You can find a job as a materials engineer after graduation and you can expect to earn a salary of around PS25,000 a year. With experience, your pay will increase significantly.

How to become a materials engineer

Materials engineers have different qualifications depending on their industry. However, most jobs require at least a bachelor's degree in materials science or engineering. This includes chemistry, mathematics, and physics.

As a materials scientist engineer, you'll need to have a bachelor's in a relevant subject such as engineering, chemistry, or physics. Most research positions at higher levels require a PhD or a Master's.

How much money can a materials engineer make?

The salaries of materials engineers can vary depending on their level of expertise, the industry in which they work and the size of the company. You can also expect bonuses and other benefits for your work.

What will the future look like for the Materials Engineering career?

The future of the materials engineering career is expected to be very good, with a lot of new opportunities opening up for those who want to get into this line of work. The increasing demand in the fields of medicine, architecture and communications for newer and more advanced materials has led to this.

You can become an engineer in materials by completing a degree program in a discipline such as metallurgy. This will give you the knowledge you need to pursue a career in this industry and may open up more opportunities for you down the line. A degree in a subject such as chemistry will help you with your research and development skills. For additional experience, it is possible to work in a company that specializes in a certain field of materials.

FAQ

How can manufacturing efficiency be improved?

First, identify the factors that affect production time. Next, we must find ways to improve those factors. If you don't know where to start, then think about which factor(s) have the biggest impact on production time. Once you have identified them, it is time to identify solutions.

What do we need to know about Manufacturing Processes in order to learn more about Logistics?

No. No. Understanding the manufacturing process will allow you to better understand logistics.

What kind of jobs are there in logistics?

There are many kinds of jobs available within logistics. These are some of the jobs available in logistics:

-

Warehouse workers - They load and unload trucks and pallets.

-

Transportation drivers: They drive trucks and trailers and deliver goods and make pick-ups.

-

Freight handlers are people who sort and pack freight into warehouses.

-

Inventory managers – They manage the inventory in warehouses.

-

Sales representatives: They sell products to customers.

-

Logistics coordinators - They organize and plan logistics operations.

-

Purchasing agents - They purchase goods and services needed for company operations.

-

Customer service representatives are available to answer customer calls and emails.

-

Shipping clerks - They process shipping orders and issue bills.

-

Order fillers - They fill orders based on what is ordered and shipped.

-

Quality control inspectors (QCI) - They inspect all incoming and departing products for potential defects.

-

Others - There are many other types of jobs available in logistics, such as transportation supervisors, cargo specialists, etc.

What skills do production planners need?

To become a successful production planner, you need to be organized, flexible, and able to multitask. Also, you must be able and willing to communicate with clients and coworkers.

What is the difference between a production planner and a project manager?

The primary difference between a producer planner and a manager of a project is that the manager usually plans and organizes the whole project, while a production planner is only involved in the planning stage.

What do you mean by warehouse?

Warehouses and storage facilities are where goods are kept before being sold. It can be either an indoor or outdoor space. It may also be an indoor space or an outdoor area.

Statistics

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

External Links

How To

How to use 5S in Manufacturing to Increase Productivity

5S stands as "Sort", Set In Order", Standardize", Separate" and "Store". Toyota Motor Corporation created the 5S methodology in 1954. It helps companies achieve higher levels of efficiency by improving their work environment.

The idea behind standardizing production processes is to make them repeatable and measurable. It means tasks like cleaning, sorting or packing, labeling, and storing are done every day. Because workers know what they can expect, this helps them perform their jobs more efficiently.

Implementing 5S involves five steps: Sort, Set in Order, Standardize Separate, Store, and Each step involves a different action which leads to increased efficiency. By sorting, for example, you make it easy to find the items later. When you arrange items, you place them together. You then organize your inventory in groups. Make sure everything is correctly labeled when you label your containers.

Employees need to reflect on how they do their jobs. Employees need to be able understand their motivations and discover alternative ways to do them. They will need to develop new skills and techniques in order for the 5S system to be implemented.

In addition to improving efficiency, the 5S system also increases morale and teamwork among employees. Once they start to notice improvements, they are motivated to keep working towards their goal of increasing efficiency.