Logistics coordinators ensure that goods arrive on time and in a cost-effective manner. As a logistics coordinator, you will make sure that the goods reach their destination on time. Learn more about logistics in this article. You'll also learn about the role of a customer service specialist, Inventory analyst, and supply chain manager. Here are some of the most important jobs you will find in logistics.

Logistics coordinator

If you want to start a career as a logistics coordinator, you can find thousands of jobs on Monster. This job requires extensive training. Candidates who do not have any experience in the field are expected to accept an apprenticeship or internship. However, they may also have industry experience. If you have extensive previous experience in the logistics field, you may also want to consider applying for a job as a logistics coordinator.

Customer service specialist

A customer service specialist is responsible for the management and delivery of customer service. They communicate with customers daily, coordinate inland transportation, and resolve customer complaints and issues. They manage customer relationships and also coordinate appointments, record special service requirements, and schedule transportation, warehousing and other activities. As a customer services specialist, you will also coordinate the documentation and ensure that all necessary documents are properly documented to ensure timely delivery and budget compliance.

Analyst for inventory

An inventory analyst is responsible for maintaining service levels and improving overall inventory productivity. Their primary duties include managing inventory replenishment and order fulfillment for TSC Feed Programs. They assist with assortment and merchandise plans by managing inventory levels within their product categories. They analyze trends and data, and plan article-site replenishment in stores. They may also help with marketing and promotion activities. They are often responsible for analysing sales data and creating new business strategies.

Supply chain manager

The supply chain manager manages the flow of goods and materials from suppliers to customers and manufacturers. The role requires a wide range of skills, and a bachelor's degree is typically required. Employers prefer candidates with master's degrees. There are several ways to be a supply-chain manager. This career field is available to learn more. If you're thinking of going into supply chain management, consider getting an associate's degree in business administration first.

Freight agent

While you're creating your job description, make sure to include a section on your cargo and freight agent responsibilities. So that potential candidates can see what they have to do every day, the job description should include a list of key responsibilities. Strong action verbs are important in your job description to attract qualified applicants. You should also provide a detailed list with qualifications that you require to fill the job.

FAQ

What is the importance of automation in manufacturing?

Not only are service providers and manufacturers important, but so is automation. It allows them provide faster and more efficient services. They can also reduce their costs by reducing human error and improving productivity.

What is the difference between Production Planning and Scheduling?

Production Planning (PP) is the process of determining what needs to be produced at any given point in time. This is done through forecasting demand and identifying production capacities.

Scheduling is the process of assigning specific dates to tasks so they can be completed within the specified timeframe.

How does a production planner differ from a project manager?

The major difference between a Production Planner and a Project Manager is that a Project Manager is often the person responsible for organizing and planning the entire project. While a Production Planner is involved mainly in the planning stage,

Can some manufacturing processes be automated?

Yes! Yes. Automation has been around since ancient time. The Egyptians discovered the wheel thousands and years ago. To help us build assembly lines, we now have robots.

Actually, robotics can be used in manufacturing for many purposes. These include:

-

Assembly line robots

-

Robot welding

-

Robot painting

-

Robotics inspection

-

Robots that make products

Automation could also be used to improve manufacturing. 3D printing is a way to make custom products quickly and without waiting weeks or months for them to be manufactured.

What does it take to run a logistics business?

To be a successful businessman in logistics, you will need many skills and knowledge. Good communication skills are essential to effectively communicate with your suppliers and clients. You should be able analyse data and draw inferences. You need to be able work under pressure and manage stressful situations. You must be creative and innovative to develop new ideas to improve efficiency. Strong leadership qualities are essential to motivate your team and help them achieve their organizational goals.

It is also important to be efficient and well organized in order meet deadlines.

What skills do production planners need?

Production planners must be flexible, organized, and able handle multiple tasks. You must also be able to communicate effectively with clients and colleagues.

Statistics

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

External Links

How To

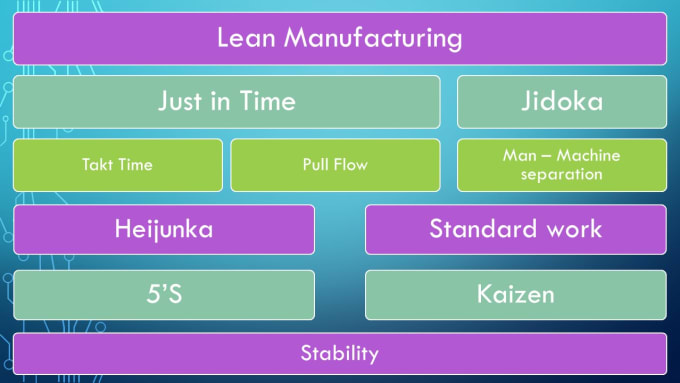

How to Use Just-In-Time Production

Just-in-time (JIT) is a method that is used to reduce costs and maximize efficiency in business processes. It allows you to get the right amount resources at the right time. This means that only what you use is charged to your account. Frederick Taylor first coined this term while working in the early 1900s as a foreman. He saw how overtime was paid to workers for work that was delayed. He concluded that if workers were given enough time before they start work, productivity would increase.

JIT is about planning ahead. You should have all the necessary resources ready to go so that you don’t waste money. Look at your entire project, from start to end. Make sure you have enough resources in place to deal with any unexpected problems. You will have the resources and people to solve any problems you anticipate. You won't have to pay more for unnecessary items.

There are many JIT methods.

-

Demand-driven JIT: You order the parts and materials you need for your project every other day. This will allow to track how much material has been used up. This will allow you to calculate how long it will take to make more.

-

Inventory-based: This type allows you to stock the materials needed for your projects ahead of time. This allows one to predict how much they will sell.

-

Project-driven: This approach involves setting aside sufficient funds to cover your project's costs. When you know how much you need, you'll purchase the appropriate amount of materials.

-

Resource-based JIT: This type of JIT is most commonly used. You allocate resources based on the demand. For example, if there is a lot of work coming in, you will have more people assigned to them. If you don't receive many orders, then you'll assign fewer employees to handle the load.

-

Cost-based: This is a similar approach to resource-based but you are not only concerned with how many people you have, but also how much each one costs.

-

Price-based pricing: This is similar in concept to cost-based but instead you look at how much each worker costs, it looks at the overall company's price.

-

Material-based is an alternative to cost-based. Instead of looking at the total cost in the company, this method focuses on the average amount of raw materials that you consume.

-

Time-based JIT is another form of resource-based JIT. Instead of focusing on the cost of each employee, you will focus on the time it takes to complete a project.

-

Quality-based JIT is another variant of resource-based JIT. Instead of thinking about the cost of each employee or the time it takes to produce something, you focus on how good your product quality.

-

Value-based JIT is the newest form of JIT. In this scenario, you're not concerned about how products perform or whether customers expect them to meet their expectations. Instead, you're focused on how much value you add to the market.

-

Stock-based: This stock-based method focuses on the actual quantity of products being made at any given time. It's useful when you want maximum production and minimal inventory.

-

Just-in-time (JIT) planning: This is a combination of JIT and supply chain management. It refers to the process of scheduling the delivery of components as soon as they are ordered. It's important as it reduces leadtimes and increases throughput.