A firm must be able to adapt to changing market conditions and stay competitive in strategic supply chain management. You need to consider several factors when selecting the best strategy. These factors include competitive positioning and cost-effectiveness as well as customer service. Additionally, the company should be prepared for investment in manufacturing infrastructure that will enable it to adapt and keep pace with changing markets.

Competitive positioning

To be competitive in a marketplace, a brand must have a competitive positioning. This involves paying close attention to customer needs and preferences, as well as current trends. It helps brands differentiate themselves from their competitors and boosts sales. It also helps brands solve customers' problems which increases their value.

A thorough market analysis is the first step to a good positioning strategy. The first step is to estimate the total market size and opportunity. This can be achieved by analyzing data from various sources including industry reports, data from the external market, and data from the company's experience in the market. This data helps to determine the potential customer base and sales. It also helps determine the nature of the market, such as growth or stability.

Cost-effectiveness

Strategic supply chains can make retailers and manufacturers more competitive. It allows firms to get a complete view of their supply chains, and can also help them to create data-driven demand forecasts. It should ultimately help companies calculate their investment costs and to explore different "what-if” scenarios.

It can also assist businesses in making better decisions and increasing their ROI. It is an essential tool for today's data driven economy. It will help decision-makers balance costs and benefits to thrive in the global economy by identifying and assessing opportunities.

Customer service

Maximizing customer service is a key aspect of strategic supply chains management. This is crucial to your business' success. This is a key aspect to your business' success. Without it, your competition will have an advantage. Only a few companies can meet customers' needs with excellence. Recent studies have shown that customers are unhappy and confused by their service experience.

Customer service is the result of several key elements that can affect the overall satisfaction of customers. These key elements include price, product quality and speed of service. Customer service, in a nutshell is a complex process that requires planning both during the transaction and before.

Infrastructural support for manufacturing

The manufacturing infrastructure is an essential element of strategic supply chain management. It ensures the timely availability of domestic industrial resources. This infrastructure includes products and human resources that form a company's supply chains. This infrastructure supports both vendor-managed and on-hand inventory. In addition, it ensures that there is adequate manufacturing capacity.

Numerous studies have shown significant savings from improving manufacturing infrastructure. Logistics, materials sourcing, as well as manufacturing capabilities can all be improved to improve the effectiveness and efficiency of supply chain operations. But many companies don’t realize that supply chain operations are not just about operational processes.

Technology

The importance of technology in strategic supply chain management is increasingly recognized as a critical part of the business success equation. In uncertain times, a more resilient and flexible supply chain is critical. Technology-enabled supply chains can reduce costs by as much as 20%, improve EBITDA by up to 10%, and enhance customer service by as much as 30%. These innovative approaches to supply chain management are the core of new business models.

Supply-chain technology adoption used to require large-scale changes within an organization. These investments were multiyear and multimillion-dollar. However, three new technologies are making it easier for companies to experiment with new strategies in an affordable, fast-paced environment. These technologies make it possible for companies to rapidly test new concepts and improve their processes. These technologies allow companies to reduce risks by implementing them in smaller and more specific areas.

FAQ

What does manufacturing mean?

Manufacturing Industries are those businesses that make products for sale. Consumers are people who purchase these goods. To accomplish this goal, these companies employ a range of processes including distribution, sales, management, and production. These companies produce goods using raw materials and other equipment. This includes all types if manufactured goods.

What is the role of a logistics manager

Logistics managers make sure all goods are delivered on schedule and without damage. This is done by using his/her experience and knowledge of the company's products. He/she should make sure that enough stock is on hand to meet the demands.

What is the difference between manufacturing and logistics

Manufacturing is the production of goods using raw materials. Logistics manages all aspects of the supply chain, including procurement, production planning and distribution, inventory control, transportation, customer service, and transport. Manufacturing and logistics can often be grouped together to describe a larger term that covers both the creation of products, and the delivery of them to customers.

What are the 4 types manufacturing?

Manufacturing is the process by which raw materials are transformed into useful products through machines and processes. It includes many different activities like designing, building and testing, packaging, shipping and selling, as well as servicing.

What is the job of a production plan?

Production planners make sure that every aspect of the project is delivered on-time, within budget, and within schedule. They also ensure that the product/service meets the client’s needs.

How can manufacturing efficiency be improved?

The first step is to identify the most important factors affecting production time. Next, we must find ways to improve those factors. If you don’t know where to begin, consider which factors have the largest impact on production times. Once you've identified them all, find solutions to each one.

What is the best way to learn about manufacturing?

You can learn the most about manufacturing by getting involved in it. If that is not possible, you could always read books or view educational videos.

Statistics

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

External Links

How To

How to use lean manufacturing in the production of goods

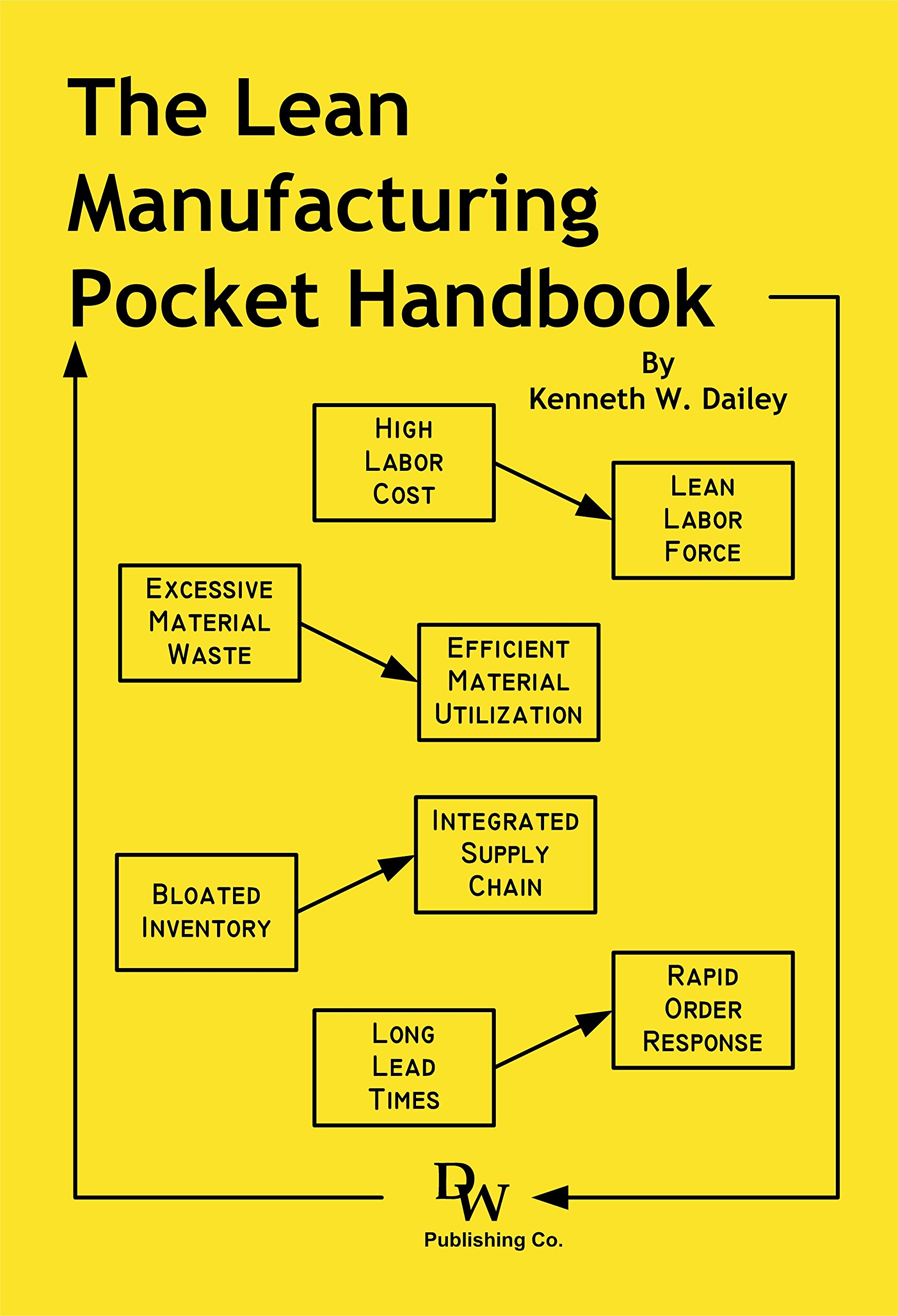

Lean manufacturing is an approach to management that aims for efficiency and waste reduction. It was developed in Japan between 1970 and 1980 by Taiichi Ohno. TPS founder Kanji Tyoda gave him the Toyota Production System, or TPS award. Michael L. Watkins published the first book on lean manufacturing in 1990.

Lean manufacturing is often defined as a set of principles used to improve the quality, speed, and cost of products and services. It emphasizes the elimination of defects and waste throughout the value stream. Just-in-time (JIT), zero defect (TPM), and 5S are all examples of lean manufacturing. Lean manufacturing seeks to eliminate non-value added activities, such as inspection, work, waiting, and rework.

Lean manufacturing improves product quality and costs. It also helps companies reach their goals quicker and decreases employee turnover. Lean manufacturing is a great way to manage the entire value chain including customers, suppliers, distributors and retailers as well as employees. Lean manufacturing is widely practiced in many industries around the world. Toyota's philosophy is a great example of this. It has helped to create success in automobiles as well electronics, appliances and healthcare.

Five basic principles of Lean Manufacturing are included in lean manufacturing

-

Define value - Find out what your business contributes to society, and what makes it different from other competitors.

-

Reduce Waste – Eliminate all activities that don't add value throughout the supply chain.

-

Create Flow. Ensure that your work is uninterrupted and flows seamlessly.

-

Standardize and Simplify – Make processes as consistent, repeatable, and as simple as possible.

-

Build Relationships - Establish personal relationships with both internal and external stakeholders.

Lean manufacturing isn’t new, but it has seen a renewed interest since 2008 due to the global financial crisis. Many businesses have adopted lean manufacturing techniques to help them become more competitive. Economists think that lean manufacturing is a crucial factor in economic recovery.

Lean manufacturing is now becoming a common practice in the automotive industry, with many benefits. These include higher customer satisfaction, lower inventory levels, lower operating expenses, greater productivity, and improved overall safety.

It can be applied to any aspect of an organisation. This is because it ensures efficiency and effectiveness in all stages of the value chain.

There are three types principally of lean manufacturing:

-

Just-in Time Manufacturing (JIT), also known as "pull system": This form of lean manufacturing is often referred to simply as "pull". JIT refers to a system in which components are assembled at the point of use instead of being produced ahead of time. This approach reduces lead time, increases availability and reduces inventory.

-

Zero Defects Manufacturing (ZDM),: ZDM is a system that ensures no defective units are left the manufacturing facility. If a part needs to be fixed during the assembly line, it should be repaired rather than scrapped. This is true even for finished products that only require minor repairs prior to shipping.

-

Continuous Improvement (CI): CI aims to improve the efficiency of operations by continuously identifying problems and making changes in order to eliminate or minimize waste. Continuous Improvement (CI) involves continuous improvement in processes, people, tools, and infrastructure.