Manufacturing Day celebrates the achievements of American manufacturers. This celebration takes place on the first Friday of October. It is also a chance to inspire the next generation of manufacturing workers to explore careers in this industry.

Manufacturing Day is celebrated by many organizations. These events are possible to be held by schools or corporations. Some events might include factory tours or presentations. Some may offer virtual information about local manufacturers. Many of these events include hands-on activities that students can participate in.

The economic vitality of manufacturers is essential. Every dollar spent in manufacturing creates $2.79 to the economy. Manufacturing is an industry that needs skilled workers. Small manufacturers spend 2.5 times as much as large manufacturers.

Manufacturing Day is supported by several federal agencies, including The Department of Education, Advanced Manufacturing Office, National Association of Manufacturers, and the Department of Education. This day provides an opportunity for manufacturers and educators to meet with local schools, communities, and businesses. These agencies can provide resources to help plan events. They also support official proclamations and factory tours.

A few companies host special seminars to inspire young people to go into manufacturing. These initiatives are also supported by The Manufacturing Institute, a National Association of Manufacturers workforce development partner. The Institute provides resources for manufacturers to help them overcome industry challenges and build stronger communities. The Institute also supports women and veterans in manufacturing.

The Biden Harris administration is working to revive manufacturing. They are focusing on building strong supply networks and investing in R&D.

AIM's 3D Virtual Reality Headsets for Students are available to them to allow them to experience advanced manufacturing occupations. AIM will work with local schools to transport students to factories that produce products. The virtual tours will allow students to get a glimpse into the manufacturing processes. The company will host virtual panels where students can discuss these topics.

Manufacturing Day celebrations include the National Strategy for Advanced Manufacturing. The Strategy encourages local manufacturers to get involved in educational programs and training programs that can benefit the local economy. Manufacturers can also organize job fairs that help people locate manufacturing opportunities.

Students can also learn about careers in manufacturing by participating in an event held by the Manufacturing Institute. This event promotes diversity and inclusion in manufacturing. Some events also feature testimonials from people who work in manufacturing.

The events hosted by the National Association of Manufacturers, the Fabricators and Manufacturers' Association, and the National Retail Federation will provide a wide variety of educational opportunities and showcase the importance of manufacturing. These events are a great way for students to learn about manufacturing's importance to the economy as well as explore the many career opportunities in this industry.

FAQ

What is the difference between Production Planning and Scheduling?

Production Planning (PP) refers to the process of determining how much production is needed at any given moment. Forecasting and identifying production capacity are two key elements to this process.

Scheduling refers to the process of allocating specific dates to tasks in order that they can be completed within a specified timeframe.

What are the goods of logistics?

Logistics are the activities involved in moving goods from point A to point B.

These include all aspects related to transport such as packaging, loading and transporting, storing, transporting, unloading and warehousing inventory management, customer service. Distribution, returns, recycling are some of the options.

Logisticians make sure that the right product arrives at the right place at the correct time and in safe conditions. Logisticians assist companies in managing their supply chains by providing information such as demand forecasts, stock levels and production schedules.

They also keep track of shipments in transit, monitor quality standards, perform inventories and order replenishment, coordinate with suppliers and vendors, and provide support services for sales and marketing.

Do we need to know about Manufacturing Processes before learning about Logistics?

No. No. However, knowing about manufacturing processes will definitely give you a better understanding of how logistics works.

What are the four types in manufacturing?

Manufacturing is the process that transforms raw materials into useful products. It can involve many activities like designing, manufacturing, testing packaging, shipping, selling and servicing.

Are there ways to automate parts of manufacturing?

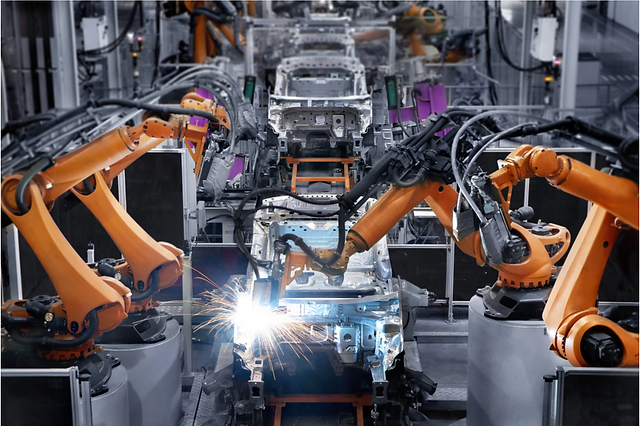

Yes! Since ancient times, automation has been in existence. The Egyptians discovered the wheel thousands and years ago. Robots are now used to assist us in assembly lines.

There are many uses of robotics today in manufacturing. These include:

-

Automation line robots

-

Robot welding

-

Robot painting

-

Robotics inspection

-

Robots that produce products

There are many other examples of how manufacturing could benefit from automation. 3D printing makes it possible to produce custom products in a matter of days or weeks.

Why is logistics important in manufacturing

Logistics are an essential component of any business. They help you achieve great results by helping you manage all aspects of product flow, from raw materials to finished goods.

Logistics plays a significant role in reducing cost and increasing efficiency.

What is the role and responsibility of a Production Planner?

Production planners make sure that every aspect of the project is delivered on-time, within budget, and within schedule. They ensure that the product or service is of high quality and meets client requirements.

Statistics

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

External Links

How To

How to Use the Just In Time Method in Production

Just-in time (JIT), is a process that reduces costs and increases efficiency in business operations. It is a process where you get the right amount of resources at the right moment when they are needed. This means that your only pay for the resources you actually use. Frederick Taylor first coined this term while working in the early 1900s as a foreman. He saw how overtime was paid to workers for work that was delayed. He decided that workers would be more productive if they had enough time to complete their work before they started to work.

JIT is about planning ahead. You should have all the necessary resources ready to go so that you don’t waste money. The entire project should be looked at from start to finish. You need to ensure you have enough resources to tackle any issues that might arise. If you anticipate that there might be problems, you'll have enough people and equipment to fix them. This way you won't be spending more on things that aren’t really needed.

There are many JIT methods.

-

Demand-driven JIT: You order the parts and materials you need for your project every other day. This will enable you to keep track of how much material is left after you use it. You'll also be able to estimate how long it will take to produce more.

-

Inventory-based: This type allows you to stock the materials needed for your projects ahead of time. This allows you to forecast how much you will sell.

-

Project-driven: This approach involves setting aside sufficient funds to cover your project's costs. If you know the amount you require, you can buy the materials you need.

-

Resource-based JIT : This is probably the most popular type of JIT. This is where you assign resources based upon demand. If you have many orders, you will assign more people to manage them. If you don't receive many orders, then you'll assign fewer employees to handle the load.

-

Cost-based: This is the same as resource-based except that you don't care how many people there are but how much each one of them costs.

-

Price-based: This is a variant of cost-based. However, instead of focusing on the individual workers' costs, this looks at the total price of the company.

-

Material-based is an alternative to cost-based. Instead of looking at the total cost in the company, this method focuses on the average amount of raw materials that you consume.

-

Time-based: This is another variation of resource-based JIT. Instead of focusing only on how much each employee is costing, you should focus on how long it takes to complete your project.

-

Quality-based JIT: This is another variation of resource based JIT. Instead of worrying about the costs of each employee or how long it takes for something to be made, you should think about how quality your product is.

-

Value-based JIT: This is the latest form of JIT. You don't worry about whether the products work or if they meet customer expectations. Instead, you're focused on how much value you add to the market.

-

Stock-based: This stock-based method focuses on the actual quantity of products being made at any given time. It's useful when you want maximum production and minimal inventory.

-

Just-in time (JIT), planning: This is a combination JIT/supply chain management. This refers to the scheduling of the delivery of components as soon after they are ordered. It's important as it reduces leadtimes and increases throughput.