The manufacturing industry is a great place to work if you're looking for a job. The manufacturing industry is continually evolving with new technology. Even if you don’t have a lot experience, college degrees are not necessary to get in this industry. Most major manufacturing firms offer on-the-job training to teach you the skills you need to advance. Continue reading to find out more about manufacturing jobs near you.

Operator of machines: Job description

If you are looking for a job as a machine operator, you can use a job description sample to get started. As a guide, you can modify the job description to fit your needs. Monster's job listings offer more inspiration. The introductory paragraph of your job description is your opportunity to market your company to potential candidates. You should describe in just two to three words what makes you unique and why this position is right for you.

Operators of machines perform many tasks. They include loading and unloading parts, operating the machines, and even operating them. They also carry out routine maintenance checks and adhere to safety regulations. They can be part of a larger team that is responsible for equipment maintenance, overseeing other operators and performing quality checks. Other duties may also be included in some job descriptions, such as helping warehouse operations. They are required to clean and inspect equipment after they have finished their work.

Manager of plastic injection mold operations

A position as a plastic injection mold operations manager requires the ability to manage the entire operation from start to end. This position has the responsibility of setting up injection molding machinery and overseeing the processing. This position requires the candidate to be familiar with managing large projects and building relationships with customers. They also need to coordinate engineering changes for existing programs. To maximize efficiency, they should be able direct the activities in the plant.

A job description should outline the responsibilities and benefits for the position. When possible, include operator qualifications and technical safety. Avoid abbreviations, and use action-oriented terminology. Mention the company's culture as well as social media presence. These details will attract qualified candidates. Your employer's job description and image should be included. It is essential that the company's image, culture, and values are maintained in order to attract qualified candidates.

The job description of an assembly line worker

Assemble products at a production line. Assigned to a part of the product's assembly, line workers must transfer the finished item to another worker. They manage the inventory and ensure product quality. It is crucial to assemble products safely, so assembly line workers need to be well-versed in safety and health practices. This is because they must work in a clean and safe environment.

It requires good hand-eye coordination and physical fitness. Assemblers can be exposed to chemicals and hazardous fumes. They must also be vigilant about machinery and tools. Failing to do this can result in serious injuries. This job requires fast thinking, good hand-eye coordination, and excellent attention to detail. Assemblers should be able communicate with other members of the assembly line station and report any malfunctioning equipment or machinery.

Manufacturing job opportunities

Manufacturing is a great place to start if you are looking for a new job. Manufacturing jobs can include program management, design engineering, quality control, and production. As you advance in the industry, you can become a quality control inspector or even manage a team. These careers are often rewarding and provide a lot of room for advancement. People with limited experience will find many opportunities in the industry. Manufacturing is the perfect career choice for recent graduates and those looking to increase their work experience or change industries.

Manufacturing careers are highly lucrative and offer a variety of post-secondary options. Your education in this field will allow you to pursue many post-secondary opportunities in a variety of fields. You can even pursue an apprenticeship or enroll in a two or four-year college to further your career. The possibilities are endless. But, manufacturing careers aren't for everyone.

FAQ

How can manufacturing reduce production bottlenecks?

Avoiding production bottlenecks is as simple as keeping all processes running smoothly, from the time an order is received until the product ships.

This includes both planning for capacity and quality control.

The best way to do this is to use continuous improvement techniques such as Six Sigma.

Six Sigma is a management method that helps to improve quality and reduce waste.

It focuses on eliminating variation and creating consistency in your work.

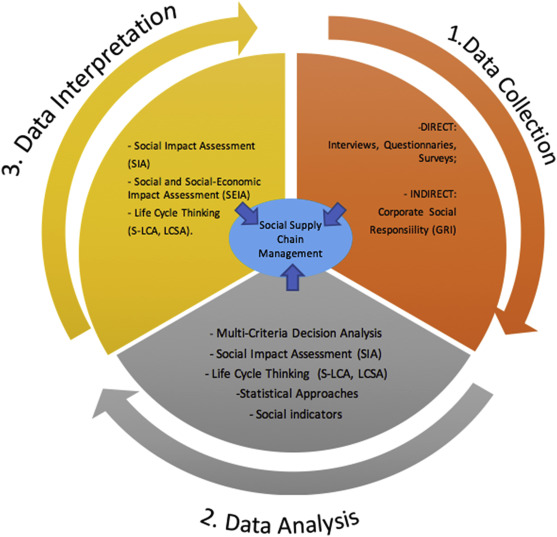

What is the difference between manufacturing and logistics

Manufacturing is the production of goods using raw materials. Logistics covers all aspects involved in managing supply chains, including procurement and production planning. Sometimes manufacturing and logistics are combined to refer to a wider term that includes both the process of creating products as well as their delivery to customers.

What is the importance of automation in manufacturing?

Not only is automation important for manufacturers, but it's also vital for service providers. It allows them provide faster and more efficient services. In addition, it helps them reduce costs by reducing human errors and improving productivity.

Statistics

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

External Links

How To

Six Sigma in Manufacturing:

Six Sigma can be described as "the use of statistical process control (SPC), techniques to achieve continuous improvement." Motorola's Quality Improvement Department in Tokyo, Japan developed Six Sigma in 1986. Six Sigma's main goal is to improve process quality by standardizing processes and eliminating defects. Many companies have adopted this method in recent years. They believe there is no such thing a perfect product or service. Six Sigma seeks to reduce variation between the mean production value. This means that you can take a sample from your product and then compare its performance to the average to find out how often the process differs from the norm. If this deviation is too big, you know something needs fixing.

Understanding the nature of variability in your business is the first step to Six Sigma. Once you have this understanding, you will need to identify sources and causes of variation. Also, you will need to identify the sources of variation. Random variations occur when people make mistakes; systematic ones are caused by factors outside the process itself. For example, if you're making widgets, and some of them fall off the assembly line, those would be considered random variations. It would be considered a systematic problem if every widget that you build falls apart at the same location each time.

Once you've identified where the problems lie, you'll want to design solutions to eliminate those problems. It might mean changing the way you do business or redesigning it entirely. After implementing the new changes, you should test them again to see if they worked. If they don't work you need to rework them and come up a better plan.