Manufacturing engineers must convert raw materials and create new, updated products. They are also responsible for creating systems that integrate the production process and supervising those who are involved in its manufacture. The career is rewarding with high levels of job satisfaction.

The average manufacturing engineer salary in the US is $77,500. This figure comes from TurboTax data of 655 users who listed their occupation as manufacturing engineer. The figures include taxable earnings, tips and bonuses.

What is the Manufacturing Engineering Salary in Canada?

Manufacturing engineering salaries range from $28,500 up to $178.500, depending on education, skills, work experience, employer and location. Experienced professionals tend to earn more than those just starting out.

Entry Level Manufacturing Engineer Salaries: The average annual salary for an entry-level manufacturing engineering is $52,000. This amount may vary from one state or another. Before applying for jobs, it is important to know what the average salary is in your state.

What are the qualification for becoming a Manufacturing Engineer?

In general, you will need to have a Bachelor's Degree in a relevant discipline. This can be an engineering specialty or a more generic subject like computer sciences or electrical engineering. It is better to get a master's degree to be able to do research or advance in your field.

What is the average job of a manufacturing engineer?

Most engineers create and develop systems which improve productivity. They are the experts that create processes for converting raw materials to finished products while focusing their efforts on eliminating wastefulness. These engineers are also highly skilled at solving problems, which allows them to identify issues and quickly solve them when creating new products or upgrading older ones.

What is the day-to-day work of manufacturing engineers?

As a manufacturing engineer, your main responsibility is to keep projects on track and budget. You also need to ensure production is efficient while maintaining high quality. They must be able to communicate effectively with design engineers, technicians and management. They must also understand how their decisions impact production cost and timelines, and how to manage these factors in a way that benefits the entire project team.

What are the qualifications for becoming an industrial & manufacturing engineer?

A manufacturing engineer is needed by almost any company with in-house production. Large multinational corporations, smaller companies, R&D labs, or local companies can all be included. These companies produce products ranging from pharmaceuticals to foods and drinks.

What are some of the most popular manufacturing engineer jobs?

A variety of industries employ manufacturing engineers. These include aerospace, defense and software and hardware development. Manufacturing engineers can work in an office or laboratory.

What is the average salary of a manufacturing engineer?

The US manufacturing engineer's salary ranges from $57,839 up to $86,809 each year. This figure was derived from data collected by 655 TurboTax customers who identified themselves as manufacturing engineers. The figures include taxable earnings, tips, bonuses, and other items.

FAQ

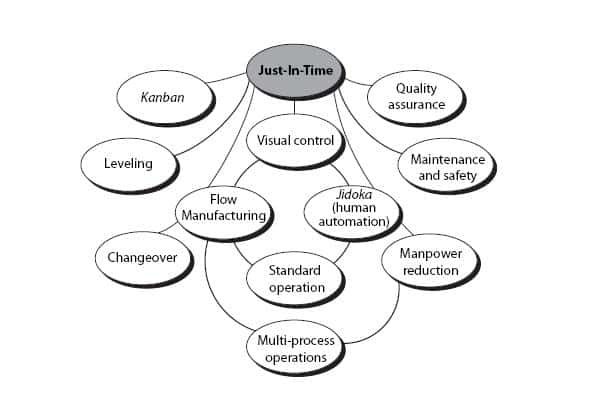

What do we need to know about Manufacturing Processes in order to learn more about Logistics?

No. It doesn't matter if you don't know anything about manufacturing before you learn about logistics. It is important to know about the manufacturing processes in order to understand how logistics works.

How can we increase manufacturing efficiency?

The first step is to identify the most important factors affecting production time. The next step is to identify the most important factors that affect production time. If you aren't sure where to begin, think about the factors that have the greatest impact on production time. Once you have identified the factors, then try to find solutions.

What are manufacturing & logistics?

Manufacturing is the production of goods using raw materials. Logistics manages all aspects of the supply chain, including procurement, production planning and distribution, inventory control, transportation, customer service, and transport. Sometimes manufacturing and logistics are combined to refer to a wider term that includes both the process of creating products as well as their delivery to customers.

Statistics

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

External Links

How To

Six Sigma: How to Use it in Manufacturing

Six Sigma is defined by "the application SPC (statistical process control) techniques to achieve continuous improvements." It was developed by Motorola's Quality Improvement Department at their plant in Tokyo, Japan, in 1986. Six Sigma's basic concept is to improve quality and eliminate defects through standardization. Since there are no perfect products, or services, this approach has been adopted by many companies over the years. Six Sigma's main objective is to reduce variations from the production average. It is possible to measure the performance of your product against an average and find the percentage of time that it differs from the norm. If the deviation is excessive, it's likely that something needs to be fixed.

Understanding the dynamics of variability within your business is the first step in Six Sigma. Once you've understood that, you'll want to identify sources of variation. These variations can also be classified as random or systematic. Random variations are caused when people make mistakes. While systematic variations are caused outside of the process, they can occur. These are, for instance, random variations that occur when widgets are made and some fall off the production line. You might notice that your widgets always fall apart at the same place every time you put them together.

Once you have identified the problem, you can design solutions. That solution might involve changing the way you do things or redesigning the process altogether. To verify that the changes have worked, you need to test them again. If they fail, you can go back to the drawing board to come up with a different plan.