Industrial engineering is a study of the interaction between people, machines (including information), equipment, and energy to produce or deliver services. It is concerned with maximizing productivity by minimizing costs, increasing quality, and maintaining a safe environment.

West Virginia engineers in demand across many industries. They use their knowledge of production, design, and operation in order to solve problems for businesses of all kinds.

Industrial engineering, unlike other forms of engineering, focuses on a big picture. The relationship between systems, people and the "right combination" of resources is what makes industrial engineering different. Industrial engineering is a broad area that requires technical and interpersonal abilities.

Professionals in this field bridge the gap between management and operations, motivating people as well as determining what tools and systems should be used and how they should be used. Computers and sophisticated software are used to ensure all systems work properly. This includes ensuring productivity, reliability and schedule adherence.

Students in this program use the knowledge and skills of mathematics, physics, statistics, engineering, and management to analyze processes, develop plans, and design equipment and processes that produce products or services. They can work on projects involving mechanical, electrical, electronic, and computer equipment.

Many college graduates with industrial engineering experiences find that they have an advantage in the job market. These graduates can enjoy higher salaries, increased responsibilities, and better work/life integration.

Co-op work is a great way for students to get real-world experience and gain knowledge while studying. They are usually with local manufacturers but they can also be found at banks, insurance companies, construction firms, and public utilities.

The University of West Virginia has a co-op program that provides students with hands-on engineering experiences. This includes calculating materials, inspecting sites and participating in field review.

Students can also get valuable work experience through internships on industrial projects. This is a fantastic opportunity to learn about the engineering field and build important relationships with potential employers.

Graduates of WV engineering programs are eligible to sit the license exam. This will help you to stand out and enhance your application.

It is important to choose the right industrial engineering program that fits your career and interests. The University of West Virginia has a wide range of industrial engineering programs that can fit your needs.

Most employers require a bachelor's degree for this career, although some universities and colleges offer graduate degrees. These programs may take several years to finish and are intended to prepare students for further studies or a future in industrial design.

The University of West Virginia provides a Bachelor's Degree in Industrial Engineering, as well several Master's Degrees. These programs prepare students to pursue careers in industrial design and for leadership roles in government, business and education. These programs have been accredited by the Accreditation Bureau for Engineering and Technology, Inc.

FAQ

What are the responsibilities for a manufacturing manager

The manufacturing manager should ensure that every manufacturing process is efficient and effective. They should also be aware and responsive to any company problems.

They should also know how to communicate with other departments such as sales and marketing.

They must also keep up-to-date with the latest trends in their field and be able use this information to improve productivity and efficiency.

How does a Production Planner differ from a Project Manager?

The primary difference between a producer planner and a manager of a project is that the manager usually plans and organizes the whole project, while a production planner is only involved in the planning stage.

How can manufacturing overproduction be reduced?

In order to reduce excess production, you need to develop better inventory management methods. This would decrease the time that is spent on inefficient activities like purchasing, storing, or maintaining excess stock. By doing this, we could free up resources for other productive tasks.

Kanban systems are one way to achieve this. A Kanban board is a visual display used to track work in progress. Kanban systems are where work items travel through a series of states until reaching their final destination. Each state represents an individual priority level.

As an example, if work is progressing from one stage of the process to another, then the current task is complete and can be transferred to the next. It is possible to keep a task in the beginning stages until it gets to the end.

This allows for work to continue moving forward, while also ensuring that there is no work left behind. With a Kanban board, managers can see exactly how much work is being done at any given moment. This data allows them adjust their workflow based upon real-time data.

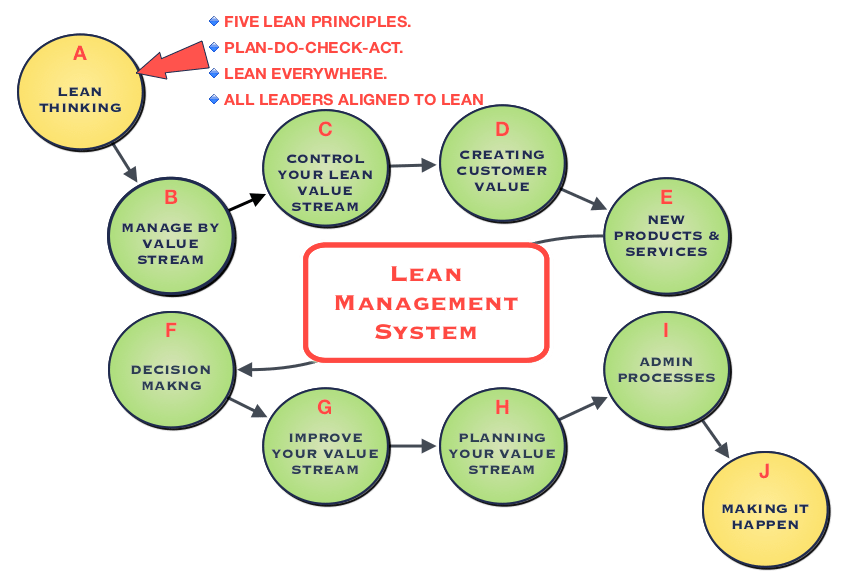

Lean manufacturing is another way to manage inventory levels. Lean manufacturing emphasizes eliminating waste in all phases of production. Anything that does nothing to add value to a product is waste. Here are some examples of common types.

-

Overproduction

-

Inventory

-

Unnecessary packaging

-

Material surplus

Manufacturers can increase efficiency and decrease costs by implementing these ideas.

What are the 7 Rs of logistics?

The acronym 7R's for Logistics stands to represent the seven basic principles in logistics management. It was developed by International Association of Business Logisticians (IABL), and published as part of their "Seven Principles of Logistics Management Series" in 2004.

The acronym consists of the following letters:

-

Responsive - ensure all actions are legal and not harmful to others.

-

Reliable - Have confidence in your ability to fulfill all of your commitments.

-

It is reasonable to use resources efficiently and not waste them.

-

Realistic – Consider all aspects, including cost-effectiveness as well as environmental impact.

-

Respectful - Treat people fairly and equitably

-

Responsive - Look for ways to save time and increase productivity.

-

Recognizable - provide customers with value-added services.

Is automation important for manufacturing?

Not only are service providers and manufacturers important, but so is automation. It allows them provide faster and more efficient services. They can also reduce their costs by reducing human error and improving productivity.

Is it possible to automate certain parts of manufacturing

Yes! Yes. Automation has been around since ancient time. The Egyptians invent the wheel thousands of year ago. We now use robots to help us with assembly lines.

There are many applications for robotics in manufacturing today. These include:

-

Automated assembly line robots

-

Robot welding

-

Robot painting

-

Robotics inspection

-

Robots that create products

Automation can be applied to manufacturing in many other ways. For example, 3D printing allows us to make custom products without having to wait for weeks or months to get them manufactured.

What jobs are available in logistics?

There are many types of jobs in logistics. Some examples are:

-

Warehouse workers: They load and unload trucks, pallets, and other cargo.

-

Transportation drivers – They drive trucks or trailers to transport goods and perform pick-ups.

-

Freight handlers, - They sort out and pack freight in warehouses.

-

Inventory managers: They are responsible for the inventory and management of warehouses.

-

Sales representatives: They sell products to customers.

-

Logistics coordinators - They plan and organize logistics operations.

-

Purchasing agents – They buy goods or services necessary to run a company.

-

Customer service agents - They answer phone calls and respond to emails.

-

Shipping clerks: They process shipping requests and issue bills.

-

Order fillers - These people fill orders based on what has been ordered.

-

Quality control inspectors - They check incoming and outgoing products for defects.

-

Others - There are many types of jobs in logistics such as transport supervisors and cargo specialists.

Statistics

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

External Links

How To

How to use the Just In-Time Production Method

Just-in time (JIT), is a process that reduces costs and increases efficiency in business operations. It's a way to ensure that you get the right resources at just the right time. This means that you only pay the amount you actually use. Frederick Taylor first coined this term while working in the early 1900s as a foreman. After observing how workers were paid overtime for late work, he realized that overtime was a common practice. He concluded that if workers were given enough time before they start work, productivity would increase.

JIT is about planning ahead. You should have all the necessary resources ready to go so that you don’t waste money. The entire project should be looked at from start to finish. You need to ensure you have enough resources to tackle any issues that might arise. You'll be prepared to handle any potential problems if you know in advance. This will ensure that you don't spend more money on things that aren't necessary.

There are many JIT methods.

-

Demand-driven: This type of JIT allows you to order the parts/materials required for your project on a regular basis. This will allow to track how much material has been used up. This will allow to you estimate the time it will take for more to be produced.

-

Inventory-based: You stock materials in advance to make your projects easier. This allows you predict the amount you can expect to sell.

-

Project-driven: This approach involves setting aside sufficient funds to cover your project's costs. When you know how much you need, you'll purchase the appropriate amount of materials.

-

Resource-based JIT is the most widespread form. Here you can allocate certain resources based purely on demand. You might assign more people to help with orders if there are many. If there aren't many orders, you will assign fewer people.

-

Cost-based: This is the same as resource-based except that you don't care how many people there are but how much each one of them costs.

-

Price-based: This is very similar to cost-based, except that instead of looking at how much each individual worker costs, you look at the overall price of the company.

-

Material-based: This approach is similar to cost-based. However, instead of looking at the total cost for the company, you look at how much you spend on average on raw materials.

-

Time-based JIT is another form of resource-based JIT. Instead of focusing only on how much each employee is costing, you should focus on how long it takes to complete your project.

-

Quality-based JIT - This is another form of resource-based JIT. Instead of focusing on the cost of each worker or how long it takes, think about how high quality your product is.

-

Value-based JIT: This is the latest form of JIT. In this instance, you are not concerned about the product's performance or meeting customer expectations. Instead, you're focused on how much value you add to the market.

-

Stock-based is an inventory-based system that measures the number of items produced at any given moment. It's used when you want to maximize production while minimizing inventory.

-

Just-intime planning (JIT), is a combination JIT/sales chain management. This refers to the scheduling of the delivery of components as soon after they are ordered. It is essential because it reduces lead-times and increases throughput.