High-paying job opportunities are available for anyone looking to enter the manufacturing industry. There are many different types of manufacturing jobs to choose from, and the skills required to qualify for some of them are different than others. Make sure to look at all options before you decide on the manufacturing career that suits your needs.

The best manufacturing careers require a combination of practical and theoretical skills, and you should set some parameters to determine which of these skills are most important to you. Ophthalmic laboratory technician is a good choice if you are interested in repair eyeglasses. If you are interested in mechanical or electrical engineering, however, these jobs may be the most lucrative.

The manufacturing industry is an important contributor to the United States economy, generating more economic activity than any other sector. It contributes to a substantial amount of the nation’s economic growth and holds a significant portion of its jobs. It is also the biggest industry in the country and has the largest economic contribution to the nation.

Advanced technical skills and experience are required for the most lucrative manufacturing jobs. However, entry-level positions do exist, and they can be a great way to get your foot in the door of the industry. They come with excellent benefits and are generally well-paid. In fact the average advertised job salary has increased by 1.5% in just the last year.

You can sign up online to get your foot into the door. A coding bootcamp can be enrolled in, as well as a formal coding class. You may already be a licensed electrician or welder and these are among the most highly-paid manufacturing jobs. A lot of companies will hire experienced manufacturing talent so you could also make good money as an independent contractor.

There are many skills required for the best manufacturing jobs. They include problem solving and critical thinking. It is possible that you will need to ensure consistency in your products and compliance with all applicable regulations. You might also want to make the most out of all technology.

A variety of manufacturing jobs are physically demanding. You'll need to frequently use heavy equipment. You may be required to work in a shop or laboratory, depending on the employer. The highest paying manufacturing jobs are the ones that require the most advanced technical skills and experience.

If you want to learn about the highest paying manufacturing jobs, you should consider the different industries and companies that are in the industry. These range from clothing manufacturers to automobile factories to electronics production sites. The process of choosing the manufacturing job that suits you best can be hard but rewarding. It's also a great way to develop your skills.

Electromechanical technicians are the highest-paid manufacturing jobs. You will be responsible to repair and maintain various manufacturing machines. To be eligible, you will need to have an engineering degree or computer science degree. However, a high school diploma is enough to get you started in the industry.

FAQ

How can we reduce manufacturing overproduction?

It is essential to find better ways to manage inventory to reduce overproduction. This would reduce the amount of time spent on unnecessary activities such as purchasing, storing, and maintaining excess stock. This will allow us to free up resources for more productive tasks.

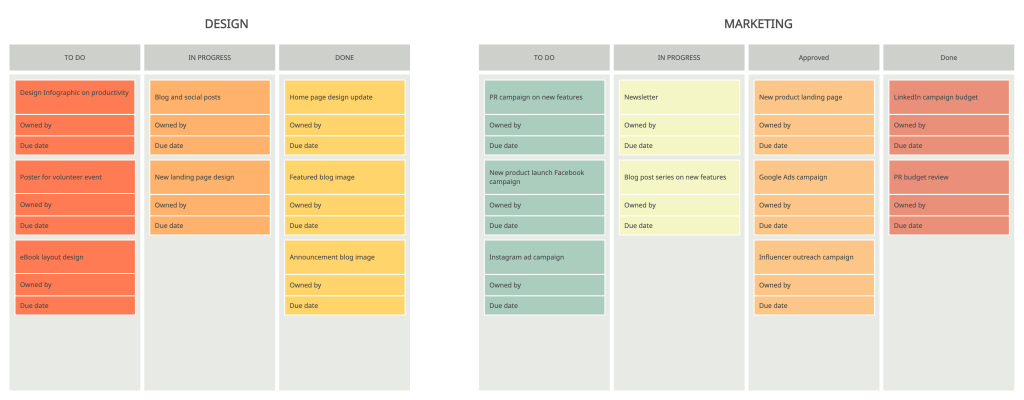

You can do this by adopting a Kanban method. A Kanban board is a visual display used to track work in progress. A Kanban system allows work items to move through several states before reaching their final destination. Each state represents a different priority level.

When work is completed, it can be transferred to the next stage. A task that is still in the initial stages of a process will be considered complete until it moves on to the next stage.

This allows for work to continue moving forward, while also ensuring that there is no work left behind. Managers can view the Kanban board to see how much work they have done. This information allows them to adjust their workflow based on real-time data.

Lean manufacturing can also be used to reduce inventory levels. Lean manufacturing seeks to eliminate waste from every step of the production cycle. Waste includes anything that does not add value to the product. There are several types of waste that you might encounter:

-

Overproduction

-

Inventory

-

Unnecessary packaging

-

Excess materials

Manufacturers can increase efficiency and decrease costs by implementing these ideas.

What are the differences between these four types?

Manufacturing refers to the transformation of raw materials into useful products by using machines and processes. Manufacturing can include many activities such as designing and building, testing, packaging shipping, selling, servicing, and other related activities.

What is production planning?

Production Planning refers to the development of a plan for every aspect of production. It is important to have everything ready and planned before you start shooting. This document should include information about how to achieve the best results on-set. This includes information on shooting times, locations, cast lists and crew details.

The first step in filming is to define what you want. You may have decided where to shoot or even specific locations you want to use. Once you have determined your scenes and locations, it is time to start figuring out the elements that you will need for each scene. You might decide you need a car, but not sure what make or model. This is where you can look up car models online and narrow down your options by choosing from different makes and models.

After you have chosen the right car, you will be able to begin thinking about accessories. Are you looking for people to sit in the front seats? You might also need someone to help you get around the back. You might want to change your interior color from black and white. These questions will help you determine the exact look and feel of your car. Also, think about what kind of shots you would like to capture. Will you be filming close-ups or wide angles? Perhaps you want to show the engine or the steering wheel? These factors will help you determine which car style you want to film.

Once you have determined all of the above, you can move on to creating a schedule. You can create a schedule that will outline when you must start and finish your shoots. Every day will have a time for you to arrive at the location, leave when you are leaving and return home when you are done. Everyone will know what they need and when. It is possible to make arrangements in advance for additional staff if you are looking to hire. You don't want to hire someone who won't show up because he didn't know.

You will need to factor in the days that you have to film when creating your schedule. Some projects can be completed in a matter of days or weeks. Others may take several days. When creating your schedule, be aware of whether you need more shots per day. Shooting multiple takes over the same location will increase costs and take longer to complete. If you aren't sure whether you need multiple shots, it is best to take fewer photos than you would like.

Budgeting is another crucial aspect of production plan. Setting a realistic budget is essential as it will allow you to work within your means. If you have to reduce your budget due to unexpected circumstances, you can always lower it later. But, don't underestimate how much money you'll spend. You will end up spending less money if you underestimate the cost of something.

Planning production is a tedious process. Once you have a good understanding of how everything works together, planning future projects becomes easy.

Can some manufacturing processes be automated?

Yes! Yes! Automation has existed since ancient times. The Egyptians invented the wheel thousands of years ago. Nowadays, we use robots for assembly lines.

In fact, there are several applications of robotics in manufacturing today. These include:

-

Line robots

-

Robot welding

-

Robot painting

-

Robotics inspection

-

Robots that create products

Manufacturing could also benefit from automation in other ways. For example, 3D printing allows us to make custom products without having to wait for weeks or months to get them manufactured.

What skills should a production planner have?

A production planner must be organized, flexible, and able multitask to succeed. You must also be able to communicate effectively with clients and colleagues.

What jobs are available in logistics?

There are many types of jobs in logistics. These are some of the jobs available in logistics:

-

Warehouse workers - They load and unload trucks and pallets.

-

Transport drivers - These are people who drive trucks and trailers to transport goods or perform pick-ups.

-

Freight handlers are people who sort and pack freight into warehouses.

-

Inventory managers – These people oversee inventory at warehouses.

-

Sales reps are people who sell products to customers.

-

Logistics coordinators are responsible for organizing and planning logistics operations.

-

Purchasing agents - They purchase goods and services needed for company operations.

-

Customer service representatives – They answer emails and phone calls from customers.

-

Shipping clerks: They process shipping requests and issue bills.

-

Order fillers: They fill orders based off what has been ordered and shipped.

-

Quality control inspectors are responsible for inspecting incoming and outgoing products looking for defects.

-

Others - There is a variety of other jobs in logistics. These include transportation supervisors and cargo specialists.

Why should you automate your warehouse?

Modern warehousing has seen automation take center stage. The rise of e-commerce has led to increased demand for faster delivery times and more efficient processes.

Warehouses must be able to quickly adapt to changing demands. Technology is essential for warehouses to be able to adapt quickly to changing needs. Automating warehouses is a great way to save money. Here are some benefits of investing in automation

-

Increases throughput/productivity

-

Reduces errors

-

Accuracy is improved

-

Safety is boosted

-

Eliminates bottlenecks

-

Allows companies to scale more easily

-

It makes workers more efficient

-

Gives you visibility into all that is happening in your warehouse

-

Enhances customer experience

-

Improves employee satisfaction

-

Minimizes downtime and increases uptime

-

This ensures that quality products are delivered promptly

-

Human error can be eliminated

-

It ensures compliance with regulations

Statistics

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

External Links

How To

Six Sigma in Manufacturing:

Six Sigma refers to "the application and control of statistical processes (SPC) techniques in order to achieve continuous improvement." Motorola's Quality Improvement Department in Tokyo, Japan developed Six Sigma in 1986. The basic idea behind Six Sigma is to improve quality by improving processes through standardization and eliminating defects. This method has been adopted by many companies in recent years as they believe there are no perfect products or services. The main goal of Six Sigma is to reduce variation from the mean value of production. If you take a sample and compare it with the average, you will be able to determine how much of the production process is different from the norm. If there is a significant deviation from the norm, you will know that something needs to change.

Understanding the nature of variability in your business is the first step to Six Sigma. Once you have a good understanding of the basics, you can identify potential sources of variation. You'll also want to determine whether these variations are random or systematic. Random variations occur when people make mistakes; systematic ones are caused by factors outside the process itself. These are, for instance, random variations that occur when widgets are made and some fall off the production line. If however, you notice that each time you assemble a widget it falls apart in exactly the same spot, that is a problem.

After identifying the problem areas, you will need to devise solutions. That solution might involve changing the way you do things or redesigning the process altogether. To verify that the changes have worked, you need to test them again. If they don’t work, you’ll need to go back and rework the plan.