There are many opportunities in maritime logistics for people who want to enter this field. This is a highly skilled industry and requires extensive training. Websites such as Shiptalk, Hellenic Shipping News and others can provide more information. This is a rewarding career.

The largest component of the maritime industry is bulk cargo. It includes general cargo ships and ore and coal carriers, as well tankers and container vessels. The loading and unloading of cargo ships used to take longer in the past than it does today. Because of this, average ships spent more time at dock than at sea. The modern technology has simplified the entire process. Shipping costs are kept low by efficiencies of scale.

As containerisation transformed freight routes, many new services were developed in late 1950s. This change has been made possible by a few technologies, including computer-aided navigation and global positioning systems. Self-unloading ships, for example, are now possible. Despite the recent declines in shipping, this industry is still very lucrative.

Similar to other industries there are many positions available in maritime logistics. For example, there is a need for logistics/embarkation specialists who are tasked with preparing supplies for embarkation. They might also be involved with force deployment planning and execution. This is a difficult role that requires deep knowledge of technology.

A shipping representative is responsible for offering competitive pricing to the company and keeping its pricing information clean and current. This person also needs to contact airlines and co-loaders to obtain the best possible rates. He or she may also be tasked with organizing company information for tender processes. This position also requires a good knowledge of port areas.

Like all other industries, maritime logistics jobs require a deep understanding of a range of subjects. This is largely due to the industry's global nature. The fact that the majority of vessels are owned and operated by companies from outside the United States can complicate matters. Thus, opportunities for sponsorship are limited. Research the industry and look at websites such as Shiptalk for information about marine logistics jobs. If you are interested, you might want to look into an apprenticeship program. These programs are available to military personnel as well. A certificate of completion will be issued upon successful completion of this program. This certificate will also give you an in-depth knowledge of the industry.

You may consider a maritime logistics job. This career offers many perks and a competitive pay. Centerline Logistics, the largest provider of marine transportation services in the United States is looking for QMED/Oilers that have at least two years experience in marine fuels.

FAQ

What is the responsibility of a manufacturing manager?

Manufacturing managers must ensure that manufacturing processes are efficient, effective, and cost-effective. They must also be alert to any potential problems and take appropriate action.

They should also know how to communicate with other departments such as sales and marketing.

They should also be knowledgeable about the latest trends in the industry so they can use this information for productivity and efficiency improvements.

What is meant by manufacturing industries?

Manufacturing Industries are those businesses that make products for sale. Consumers are people who purchase these goods. To accomplish this goal, these companies employ a range of processes including distribution, sales, management, and production. They produce goods from raw materials by using machines and other machinery. This includes all types of manufactured goods, including food items, clothing, building supplies, furniture, toys, electronics, tools, machinery, vehicles, pharmaceuticals, medical devices, chemicals, and many others.

What do you mean by warehouse?

A warehouse is a place where goods are stored until they are sold. It can be indoors or out. It could be one or both.

Statistics

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

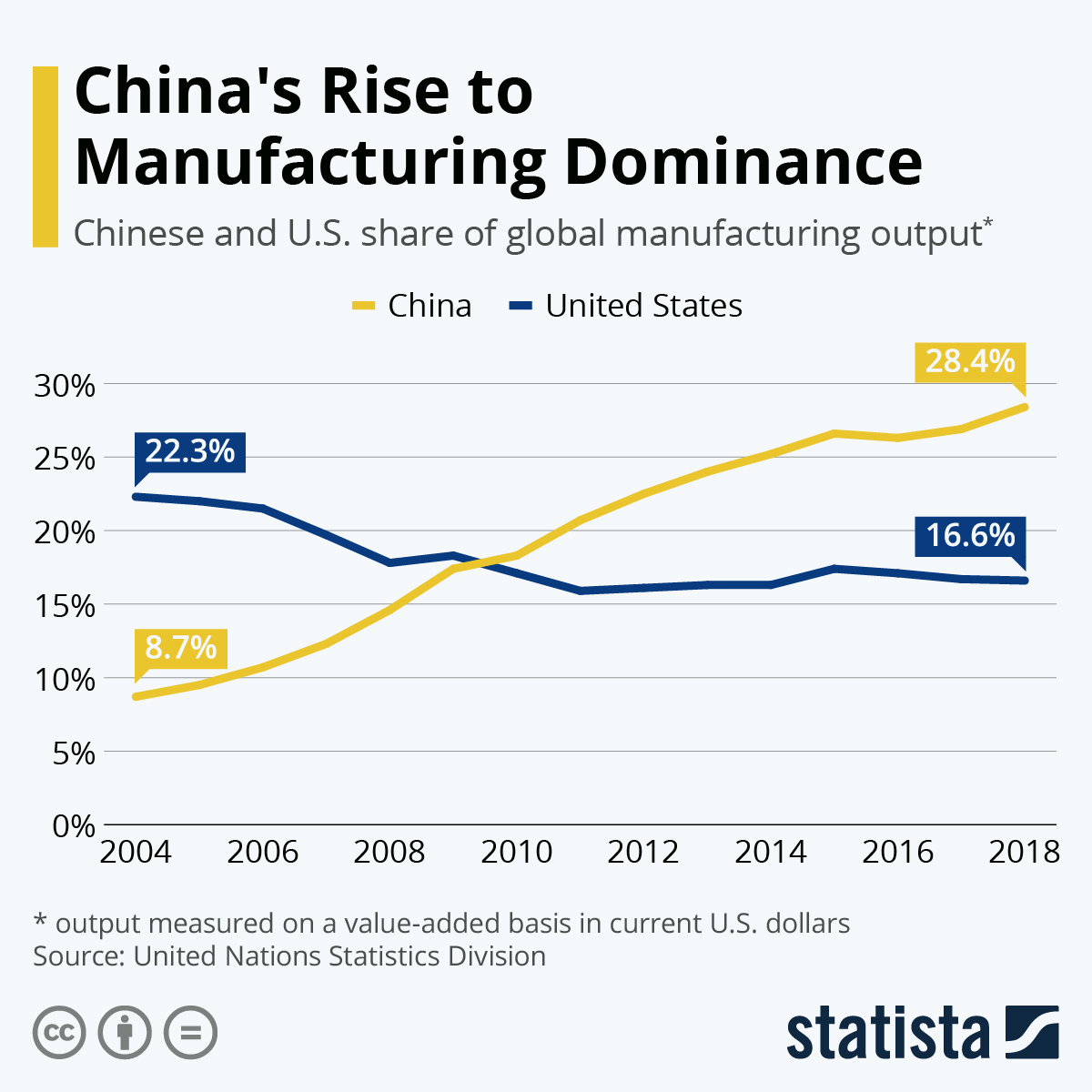

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

External Links

How To

How to Use Lean Manufacturing in the Production of Goods

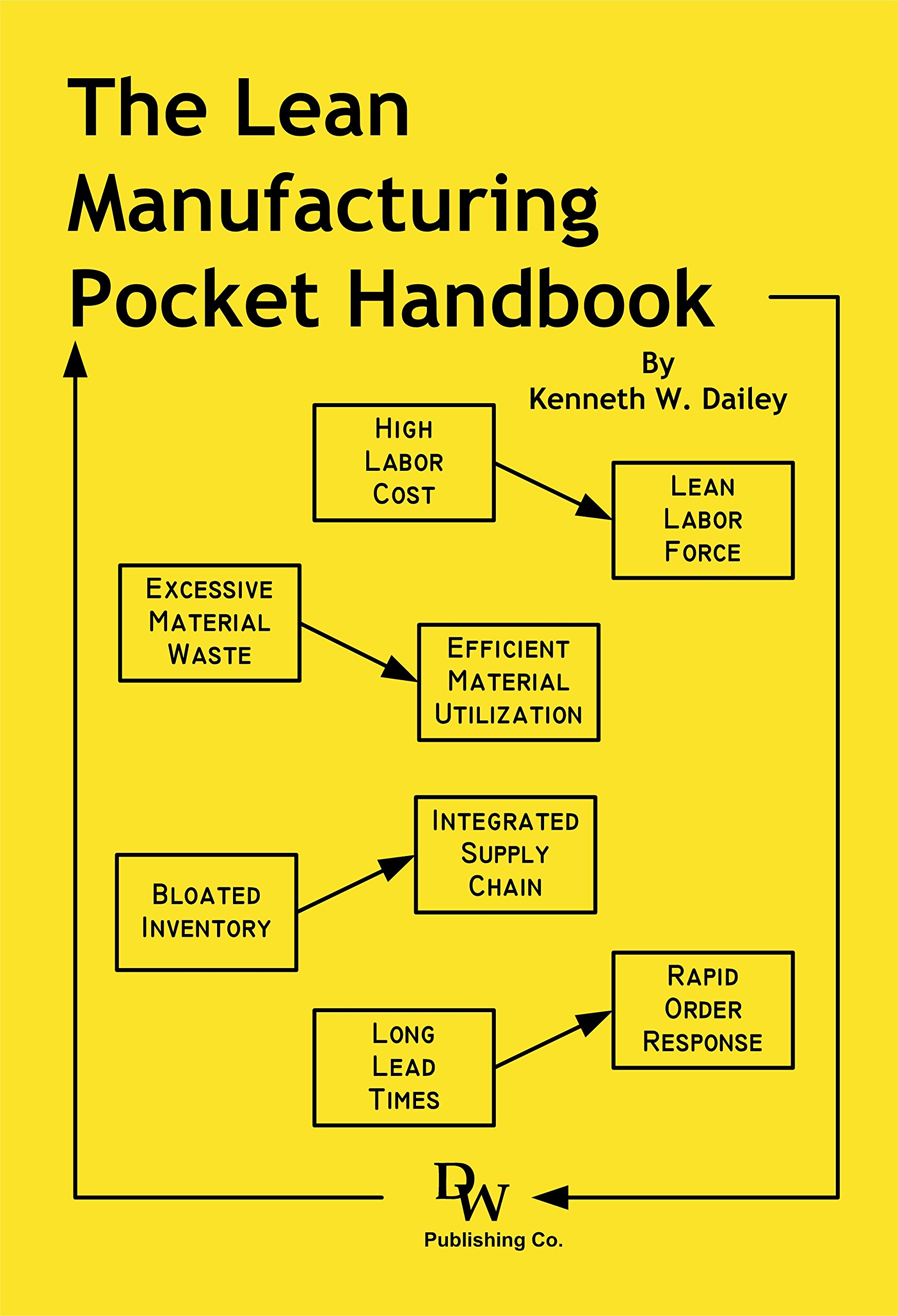

Lean manufacturing refers to a method of managing that seeks to improve efficiency and decrease waste. It was developed by Taiichi Okono in Japan, during the 1970s & 1980s. TPS founder Kanji Takoda awarded him the Toyota Production System Award (TPS). Michael L. Watkins published the book "The Machine That Changed the World", which was the first to be published about lean manufacturing.

Lean manufacturing refers to a set of principles that improve the quality, speed and costs of products and services. It emphasizes eliminating waste and defects throughout the value stream. Lean manufacturing can be described as just-in–time (JIT), total productive maintenance, zero defect (TPM), or even 5S. Lean manufacturing eliminates non-value-added tasks like inspection, rework, waiting.

Lean manufacturing can help companies improve their product quality and reduce costs. Additionally, it helps them achieve their goals more quickly and reduces employee turnover. Lean manufacturing is a great way to manage the entire value chain including customers, suppliers, distributors and retailers as well as employees. Lean manufacturing practices are widespread in many industries. For example, Toyota's philosophy underpins its success in automobiles, electronics, appliances, healthcare, chemical engineering, aerospace, paper, food, etc.

Five fundamental principles underlie lean manufacturing.

-

Define Value - Determine the value that your business brings to society. Also, identify what sets you apart from your competitors.

-

Reduce Waste - Remove any activity which doesn't add value to your supply chain.

-

Create Flow: Ensure that the work process flows without interruptions.

-

Standardize & Simplify - Make processes as consistent and repeatable as possible.

-

Build Relationships- Develop personal relationships with both internal as well as external stakeholders.

Although lean manufacturing has always been around, it is gaining popularity in recent years because of a renewed interest for the economy after 2008's global financial crisis. Many businesses have adopted lean production techniques to make them more competitive. According to some economists, lean manufacturing could be a significant factor in the economic recovery.

With many benefits, lean manufacturing is becoming more common in the automotive industry. These include better customer satisfaction and lower inventory levels. They also result in lower operating costs.

It can be applied to any aspect of an organisation. Because it makes sure that all value chains are efficient and effectively managed, Lean Manufacturing is particularly helpful for organizations.

There are three main types of lean manufacturing:

-

Just-in Time Manufacturing (JIT), also known as "pull system": This form of lean manufacturing is often referred to simply as "pull". JIT means that components are assembled at the time of use and not manufactured in advance. This method reduces lead times, increases availability, and decreases inventory.

-

Zero Defects Manufacturing, (ZDM): ZDM is focused on ensuring that no defective products leave the manufacturing facility. If a part needs to be fixed during the assembly line, it should be repaired rather than scrapped. This applies to finished products, which may need minor repairs before they are shipped.

-

Continuous Improvement (CI: Continuous improvement aims to increase the efficiency of operations by constantly identifying and making improvements to reduce or eliminate waste. It involves continuous improvement of processes, people, and tools.