Knowing what to expect is key to earning a Supply Chain Management Certificate. This degree program, which is meant for working professionals, emphasizes simulations and case materials as well experiential learning. Throughout your coursework, you'll be working alongside supply chain industry experts and other peers. The final project or capstone project will require you to work with a company to solve a problem. This article will help you decide if you want to pursue a degree in business administration.

Coursework

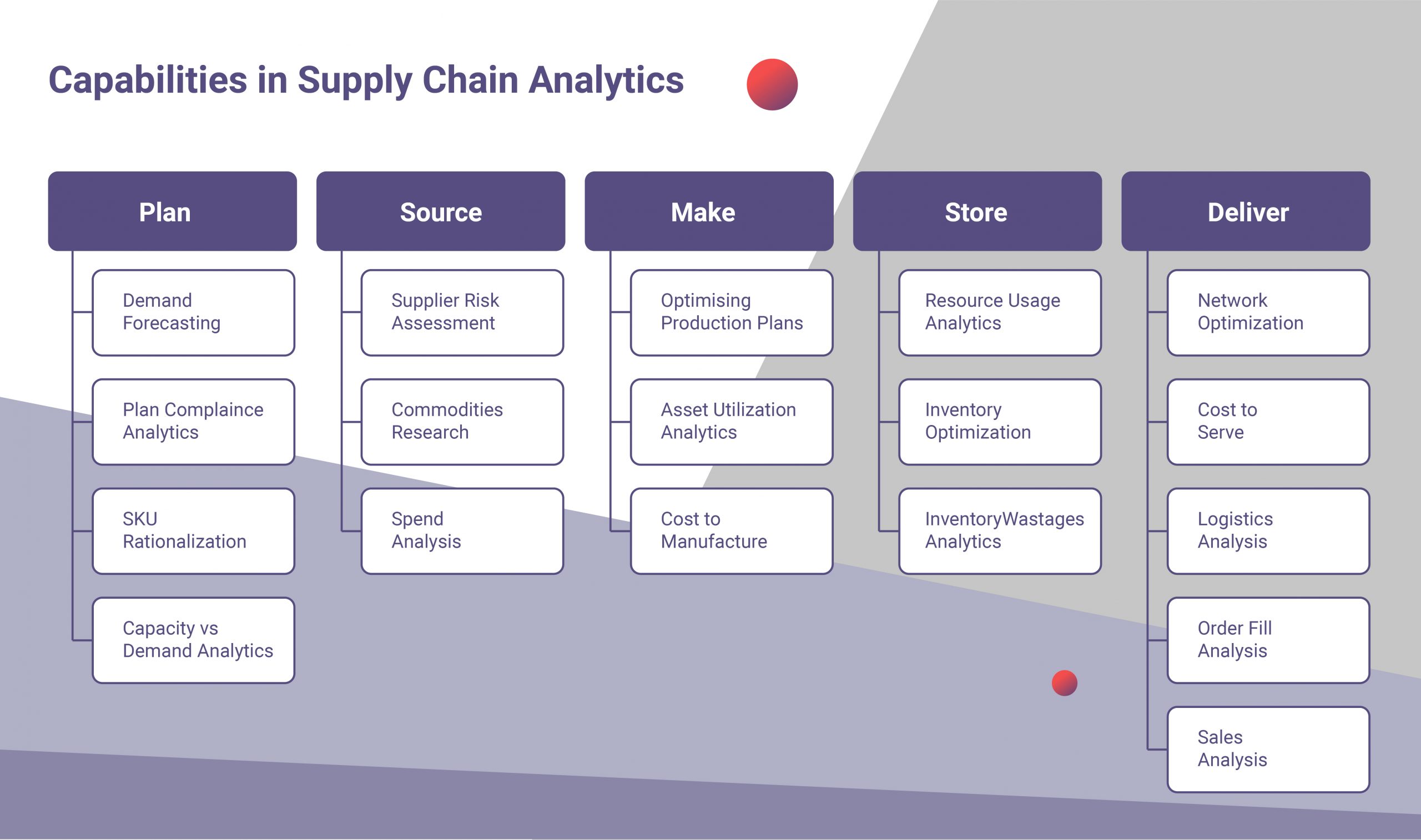

The Coursework for Supply Chain Management Certificate includes four courses. This program will give you the fundamentals. This program covers topics such customer demand forecasting as well as master production scheduling, inventory planning, capacity planning and capacity planning. It also provides you with essential information necessary to pass the supply chain management certification exam. Students will be taught how to use practical solutions to improve their performance and reduce costs. You will also gain a global perspective and understanding of the key drivers of supply chain management in this curriculum.

To obtain this certification, students must take the required courses and pass the certificate exam. The American Production and Inventory Control Society is the industry standard for the examination. Companies in the manufacturing and supply chain management sectors will look for APICS certification when hiring new employees. The course assumes a full-time credit load of 12 credits per semester. Once enrolled in the program, students must submit a resume and interview with faculty and staff at the Grainger Center to complete their degree.

Prerequisites

You must meet the prerequisites to be eligible for a supply chain management certificate. Whether you are an experienced supply chain management professional or a graduate of a general management program, this certificate is designed for you. This course will prepare you to sit for a certification exam. This course emphasizes key performance indicators such customer satisfaction as well as environmental impact.

The requirements for this certificate depend on the place you will be completing the program. A bachelor's degree is required in business or supply-chain management. However individuals with no SCM experience are welcome to apply. Before applying, you should speak to your advisor if in doubt about whether or not a specific degree will be required. You will be able to build a strong foundation in supply chain management by taking the prerequisite courses. However, you might want to take a few electives to tailor your education to your needs.

Certifications

You can further your career by obtaining supply chain management certifications. Many supply chain certifications were based on real world scenarios. They can also be practical and helpful, as they allow you to show your expertise. These certifications will be most useful for students who are just starting out in supply chain, but are looking to expand their knowledge. These are just a few examples of supply chain certifications. Continue reading to find out more. We have listed some of the most common certifications, and explained what they mean.

ASCM credential Certified in Production and Inventory Management is the CPIM certification. It certifies that a supply-chain manager has extensive knowledge of operations and inventory control. The certification requires that you pass two exams in three years. CPIM Part 1 focuses primarily upon fundamentals of supply chains management. CPIM Part 2 focuses mainly on scheduling, resources, as well as the overall operation and management of a supply system. You should remember that the CPIM certification is contingent on the candidate earning 75 professional development points.

Internships

An internship certificate in supply-chain management is a great start for someone who wants to work in a related field. The supply chain is not as easy to set up and forget like other types jobs. Each business has its specific set of processes, capabilities, and this applies to a trucking company's supply network. Internships in supply chains provide students with hands-on experience while gaining foundational knowledge and practical skills.

Students seeking to obtain supply chain management certificate internships should be mindful not to neglect their studies. A high GPA indicates drive, focus, and intelligence. Your chances of success can be boosted by a strong resume and good interpersonal skills. A college advisor will be able help you to polish your resume. Translating skills from one language can be tricky. It is best to consult a career adviser as well as a college advisor.

FAQ

What are the logistics products?

Logistics refers to the movement of goods from one place to another.

They include all aspects associated with transport including packaging, loading transporting, unloading storage, warehousing inventory management customer service, distribution returns and recycling.

Logisticians ensure that products reach the right destination at the right moment and under safe conditions. Logisticians help companies improve their supply chain efficiency by providing information about demand forecasts and stock levels, production schedules, as well as availability of raw materials.

They can also track shipments in transit and monitor quality standards.

Why is logistics important in manufacturing?

Logistics are an integral part any business. They can help you achieve great success by helping you manage product flow from raw material to finished goods.

Logistics are also important in reducing costs and improving efficiency.

What are the responsibilities of a production planner

Production planners ensure that all project aspects are completed on time, within budget and within the scope. They ensure that the product or service is of high quality and meets client requirements.

How can excess manufacturing production be reduced?

In order to reduce excess production, you need to develop better inventory management methods. This would reduce the time spent on unproductive activities like purchasing, storing and maintaining excess stock. This would allow us to use our resources for more productive tasks.

A Kanban system is one way to achieve this. A Kanban board, a visual display to show the progress of work, is called a Kanban board. Kanban systems are where work items travel through a series of states until reaching their final destination. Each state represents an individual priority level.

When work is completed, it can be transferred to the next stage. However, if a task is still at the beginning stages, it will remain so until it reaches the end of the process.

This allows for work to continue moving forward, while also ensuring that there is no work left behind. A Kanban board allows managers to monitor how much work is being completed at any given moment. This data allows them adjust their workflow based upon real-time data.

Lean manufacturing is another way to manage inventory levels. Lean manufacturing works to eliminate waste throughout every stage of the production chain. Anything that does not contribute to the product's value is considered waste. These are some of the most common types.

-

Overproduction

-

Inventory

-

Packaging not required

-

Materials in excess

By implementing these ideas, manufacturers can improve efficiency and cut costs.

What is production plan?

Production planning is the process of creating a plan that covers all aspects of production. This includes scheduling, budgeting and crew, location, equipment, props, and more. This document is designed to make sure everything is ready for when you're ready to shoot. It should also provide information about how best to produce the best results while on set. It should include information about shooting locations, casting lists, crew details, equipment requirements, and shooting schedules.

It is important to first outline the type of film you would like to make. You may have already chosen the location you want, or there are locations or sets you prefer. Once you have identified your locations and scenes, you can start working out which elements you require for each scene. Perhaps you have decided that you need to buy a car but aren't sure which model. To narrow your options, you can search online for available models.

After you have chosen the right car, you will be able to begin thinking about accessories. You might need to have people in the front seats. You might also need someone to help you get around the back. Maybe you want to change the interior color from black to white? These questions will help you determine the exact look and feel of your car. The type of shots that you are looking for is another thing to consider. Do you want to film close-ups, or wider angles? Maybe you want the engine or the steering wheels to be shown. All of these things will help you identify the exact style of car you want to film.

Once you have all the information, you are ready to create a plan. The schedule will show you when to begin shooting and when to stop. Each day will include the time when you need to arrive at the location, when you need to leave and when you need to return home. So everyone is clear about what they need to do. Hire extra staff by booking them ahead of time. You don't want to hire someone who won't show up because he didn't know.

Your schedule will also have to be adjusted to reflect the number of days required to film. Some projects take only a few days while others can last several weeks. When you are creating your schedule, you should always keep in mind whether you need more than one shot per day or not. Shooting multiple takes over the same location will increase costs and take longer to complete. It is better to be cautious and take fewer shots than you risk losing money if you are not sure if multiple takes are necessary.

Budgeting is another important aspect of production planning. A realistic budget will help you work within your means. Keep in mind that you can always reduce your budget if you face unexpected difficulties. You shouldn't underestimate the amount you'll spend. You'll end up with less money after paying for other things if the cost is underestimated.

Production planning is a complicated process. But once you understand how everything works together, it becomes much easier to plan future project.

Statistics

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

External Links

How To

How to Use Just-In-Time Production

Just-in-time is a way to cut costs and increase efficiency in business processes. It is a process where you get the right amount of resources at the right moment when they are needed. This means that only what you use is charged to your account. Frederick Taylor, a 1900s foreman, first coined the term. He observed how workers were paid overtime if there were delays in their work. He decided to ensure workers have enough time to do their jobs before starting work to improve productivity.

JIT teaches you to plan ahead and prepare everything so you don’t waste time. Look at your entire project, from start to end. Make sure you have enough resources in place to deal with any unexpected problems. You will have the resources and people to solve any problems you anticipate. This way you won't be spending more on things that aren’t really needed.

There are different types of JIT methods:

-

Demand-driven JIT: You order the parts and materials you need for your project every other day. This will allow for you to track the material that you have left after using it. It will also allow you to predict how long it takes to produce more.

-

Inventory-based: This allows you to store the materials necessary for your projects in advance. This allows for you to anticipate how much you can sell.

-

Project-driven: This means that you have enough money to pay for your project. Knowing how much money you have available will help you purchase the correct amount of materials.

-

Resource-based JIT is the most widespread form. This is where you assign resources based upon demand. You will, for example, assign more staff to deal with large orders. If you don't have many orders, you'll assign fewer people to handle the workload.

-

Cost-based: This is the same as resource-based except that you don't care how many people there are but how much each one of them costs.

-

Price-based: This is very similar to cost-based, except that instead of looking at how much each individual worker costs, you look at the overall price of the company.

-

Material-based: This approach is similar to cost-based. However, instead of looking at the total cost for the company, you look at how much you spend on average on raw materials.

-

Time-based JIT: This is another variant of resource-based JIT. Instead of focusing on the cost of each employee, you will focus on the time it takes to complete a project.

-

Quality-based JIT - This is another form of resource-based JIT. Instead of worrying about the costs of each employee or how long it takes for something to be made, you should think about how quality your product is.

-

Value-based JIT: This is the latest form of JIT. You don't worry about whether the products work or if they meet customer expectations. Instead, your focus is on the value you bring to the market.

-

Stock-based. This method is inventory-based and focuses only on the actual production at any given point. It is used when production goals are met while inventory is kept to a minimum.

-

Just-intime planning (JIT), is a combination JIT/sales chain management. It is the process that schedules the delivery of components within a short time of their order. It is essential because it reduces lead-times and increases throughput.