Many skills are needed to work in railway logistics. Some jobs are very easy to learn while others require extensive classroom training and years of experience. These jobs require advanced product knowledge and computer proficiency. Other jobs may require considerable overseas travel.

Transport logistics specialists are experts in coordinating and managing the movement of people or materials. The specialist may assess the efficiency of the process and find solutions to specific problems. This could include a mechanical check or determining which route is best for a particular cargo.

The rail logistics manager has the responsibility of ensuring that trains, buses and other transport means are in good condition and running on time. They are responsible for ensuring that trains adhere to safety regulations and rules. Freight delivery is often part of the job. However, this is just one aspect of the job.

Intermodal dispatcher, another entry-level job in this industry, is also available. This person coordinates the schedule of a group of drivers and a shipping company. The person coordinates the schedule of a group of drivers and a shipping company. It is not uncommon for this position also to include administrative duties.

A railway logistics manager could also choose to work in a privately owned company or government agency. These roles are well-paying and offer great career advancement opportunities. On average, you can earn approximately $45,000 per annum. A bachelor's degree is not required for most of these jobs. Despite the high wages, the average rail salary remains quite low.

You might find logistics managers, logistics analysts and logistics coordinators. These are all important positions in the field. Each of these roles has its own merits, but there is a good chance that your skills will be better utilized in one of these roles than in the other.

Logistics managers need to be able negotiate the best terms and rates for their company's transportation needs. This involves analysing the availability of equipment, services, negotiating and analyzing service level. They must also be able apply basic transport management concepts to increase the efficiency of their company’s logistics processes.

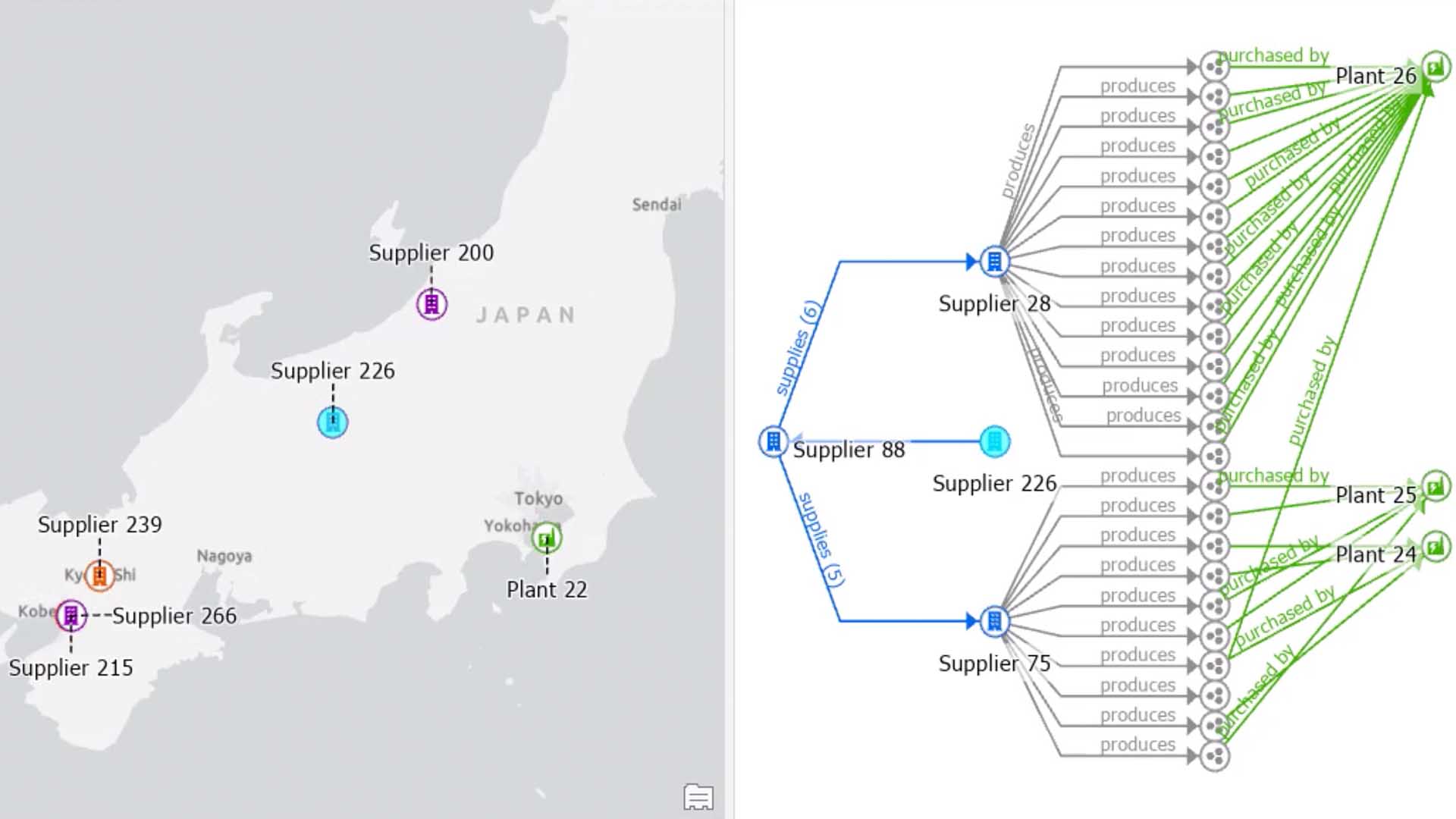

Rail logistics managers might oversee the installation of a state of the art tracking system to track and deliver goods on time. A tracking system may be used to alert customers about the current location of a shipment.

The rail logistics manager might also be called upon to advise on ways to increase efficiency in transportation. He or she will be able help their company achieve more results in a less time.

Many of these positions can be learned by doing on-the-job training and experience. Rail logistics coordinators, on the other side, require a bachelor's and years of relevant experience.

FAQ

What is the role of a production manager?

Production planners make sure that every aspect of the project is delivered on-time, within budget, and within schedule. They ensure that the product or service is of high quality and meets client requirements.

What does "warehouse" mean?

A warehouse is an area where goods are stored before being sold. You can have it indoors or outdoors. Sometimes, it can be both an indoor and outdoor space.

What is the difference between a production planner and a project manager?

The primary difference between a producer planner and a manager of a project is that the manager usually plans and organizes the whole project, while a production planner is only involved in the planning stage.

What is meant by manufacturing industries?

Manufacturing Industries are those businesses that make products for sale. The people who buy these products are called consumers. These companies use a variety processes such as distribution, retailing and management to accomplish their purpose. They create goods from raw materials, using machines and various other equipment. This covers all types of manufactured goods including clothing, food, building supplies and furniture, as well as electronics, tools, machinery, vehicles and pharmaceuticals.

Statistics

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

External Links

How To

How to Use 5S for Increasing Productivity in Manufacturing

5S stands to stand for "Sort", “Set In Order", “Standardize", and "Store". Toyota Motor Corporation developed the 5S method in 1954. It helps companies achieve higher levels of efficiency by improving their work environment.

This approach aims to standardize production procedures, making them predictable, repeatable, and easily measurable. It means tasks like cleaning, sorting or packing, labeling, and storing are done every day. These actions allow workers to perform their job more efficiently, knowing what to expect.

There are five steps to implementing 5S, including Sort, Set In Order, Standardize, Separate and Store. Each step involves a different action which leads to increased efficiency. By sorting, for example, you make it easy to find the items later. You arrange items by placing them in an order. Next, organize your inventory into categories and store them in containers that are easily accessible. Labeling your containers will ensure that everything is correctly labeled.

This requires employees to critically evaluate how they work. Employees need to understand the reasons they do certain jobs and determine if there is a better way. To be successful in the 5S system, employees will need to acquire new skills and techniques.

The 5S method increases efficiency and morale among employees. They will feel motivated to strive for higher levels of efficiency once they start to see results.