If you're looking for a career in manufacturing, there are plenty of options in Houston, Texas. These jobs are available in multiple industries and range from entry-level to highly-paid. Register for free at Monster to get started. You will receive job alerts tailored to your needs and expert advice. By using this free website, you can find manufacturing jobs in Houston that meet your needs.

Entry-level jobs

Looking for a new job in Houston? There are many jobs available in the Houston area. Knowing what you want is the best way for you to find it. To find the right job, you can search online or visit your local job center.

High-paying Jobs

The state of Texas has many manufacturing jobs that pay well. According to Brookings Institution in Texas, manufacturing jobs are high-paying. Average wages in Texas for automotive-related manufacturing positions was $60,700 in 2016. Upper East Texas is where the majority of manufacturing jobs for travel trailers and truck trailers are located.

Texas' manufacturing sector is an important contributor to the local economy. This industry creates jobs for many service providers, parts suppliers and distributors as well as transportation companies. The Comptroller of Texas claims that nearly 2.2 Million jobs are supported by the state’s manufacturing sector. Texas's manufacturing sector contributes nearly 25% of Texas’s economy.

Diverse industries

Houston is home to many manufacturing jobs. More than half of these jobs are in the production of durable goods. These include oil field equipment, structural steel, and computers. Houston's manufacturing sector supports over 40,000 jobs and is expanding at a rapid rate. This sector has a 2.4 percent annual increase in employment.

The manufacturing industry supplies the parts and products almost everyone uses every day. Manufacturing jobs in Houston range from aerospace and biotechnology. Some industries are at the forefront of technology, while others make everyday products. No matter what your interests are, there is a job for you.

Houston's manufacturing industries are one of the major economic drivers in the area. It creates jobs in many other sectors and services. It also sparks innovation. Many of these industries heavily invest in research and innovation. High wages are a result. Texas has more than $57,000 in annual wages for manufacturing jobs.

FAQ

Why automate your factory?

Modern warehousing is becoming more automated. E-commerce has brought increased demand for more efficient and quicker delivery times.

Warehouses must be able to quickly adapt to changing demands. Technology investment is necessary to enable warehouses to respond quickly to changing demands. Automating warehouses has many benefits. Here are some of the reasons automation is worth your investment:

-

Increases throughput/productivity

-

Reduces errors

-

Accuracy is improved

-

Safety is boosted

-

Eliminates bottlenecks

-

Allows companies scale more easily

-

It makes workers more efficient

-

The warehouse can be viewed from all angles.

-

Enhances customer experience

-

Improves employee satisfaction

-

Minimizes downtime and increases uptime

-

High quality products delivered on-time

-

Human error can be eliminated

-

Assure compliance with regulations

What does the term manufacturing industries mean?

Manufacturing Industries refers to businesses that manufacture products. Consumers are the people who purchase these products. These companies use various processes such as production, distribution, retailing, management, etc., to fulfill this purpose. They manufacture goods from raw materials using machines and other equipment. This includes all types and varieties of manufactured goods, such as food items, clothings, building supplies, furnitures, toys, electronics tools, machinery vehicles, pharmaceuticals medical devices, chemicals, among others.

What skills is required for a production planner?

Production planners must be flexible, organized, and able handle multiple tasks. You must also be able to communicate effectively with clients and colleagues.

What does it mean to warehouse?

Warehouses and storage facilities are where goods are kept before being sold. It can be either an indoor or outdoor space. Sometimes, it can be both an indoor and outdoor space.

What is production planning?

Production planning is the process of creating a plan that covers all aspects of production. This includes scheduling, budgeting and crew, location, equipment, props, and more. This document is designed to make sure everything is ready for when you're ready to shoot. This document should include information about how to achieve the best results on-set. This includes location information, crew details, equipment specifications, and casting lists.

The first step is to outline what you want to film. You may have already decided where you would like to shoot, or maybe there are specific locations or sets that you want to use. Once you have identified your locations and scenes, you can start working out which elements you require for each scene. If you decide you need a car and don't know what model to choose, this could be an example. In this case, you could start looking up cars online to find out what models are available and then narrow your choices by choosing between different makes and models.

Once you have found the right car, you can start thinking about extras. What about additional seating? You might also need someone to help you get around the back. You may want to change the interior's color from black or white. These questions can help you decide the right look for your car. Also, think about what kind of shots you would like to capture. Do you want to film close-ups, or wider angles? Maybe you want to show the engine and the steering wheel. These details will help identify the exact car you wish to film.

Once you have determined all of the above, you can move on to creating a schedule. A schedule will tell you when you need to start shooting and when you need to finish. You will need to know when you have to be there, what time you have to leave and when your return home. This way, everyone knows what they need to do and when. If you need to hire extra staff, you can make sure you book them in advance. You don't want to hire someone who won't show up because he didn't know.

Your schedule will also have to be adjusted to reflect the number of days required to film. Some projects only take one or two days, while others may last weeks. It is important to consider whether you require more than one photo per day when you create your schedule. Multiple takes at the same place will result in higher costs and longer completion times. It's better to be safe than sorry and shoot less takes if you're not certain whether you need more takes.

Another important aspect of production planning is setting budgets. It is important to set a realistic budget so you can work within your budget. Remember that you can always reduce the budget later on if you run into unforeseen problems. You shouldn't underestimate the amount you'll spend. If you underestimate how much something costs, you'll have less money to pay for other items.

Planning production is a tedious process. Once you have a good understanding of how everything works together, planning future projects becomes easy.

What's the difference between Production Planning & Scheduling?

Production Planning (PP), or production planning, is the process by which you determine what products are needed at any given time. This is done through forecasting demand and identifying production capacities.

Scheduling involves the assignment of dates and times to tasks in order to complete them within the timeframe.

Statistics

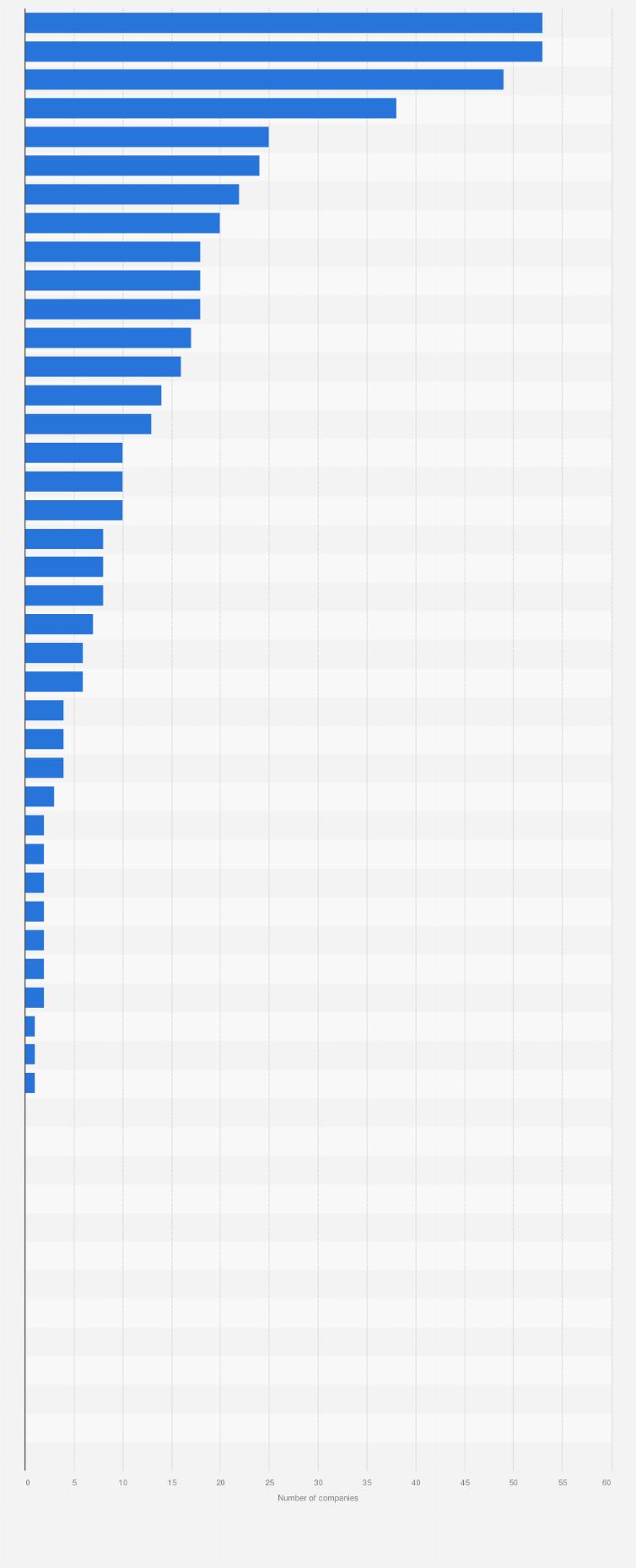

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

External Links

How To

How to Use 5S for Increasing Productivity in Manufacturing

5S stands for "Sort", 'Set In Order", 'Standardize', & Separate>. Toyota Motor Corporation created the 5S methodology in 1954. It assists companies in improving their work environments and achieving higher efficiency.

This method has the basic goal of standardizing production processes to make them repeatable. This means that daily tasks such as cleaning and sorting, storage, packing, labeling, and packaging are possible. Because workers know what they can expect, this helps them perform their jobs more efficiently.

Five steps are required to implement 5S: Sort, Set In Order, Standardize. Separate. Each step requires a different action to increase efficiency. By sorting, for example, you make it easy to find the items later. You arrange items by placing them in an order. After you have divided your inventory into groups you can store them in easy-to-reach containers. Make sure everything is correctly labeled when you label your containers.

Employees must be able to critically examine their work practices. Employees need to understand the reasons they do certain jobs and determine if there is a better way. To be successful in the 5S system, employees will need to acquire new skills and techniques.

In addition to increasing efficiency, the 5S method also improves morale and teamwork among employees. As they begin to see improvements, they feel motivated to continue working towards the goal of achieving higher levels of efficiency.